Success Stories

How HLS Linen Optimized Efficiency by Automating Fugitive Lint Management

Understanding the Risk of Overhead Lint Buildup

Understanding the Risk of Overhead Lint Buildup

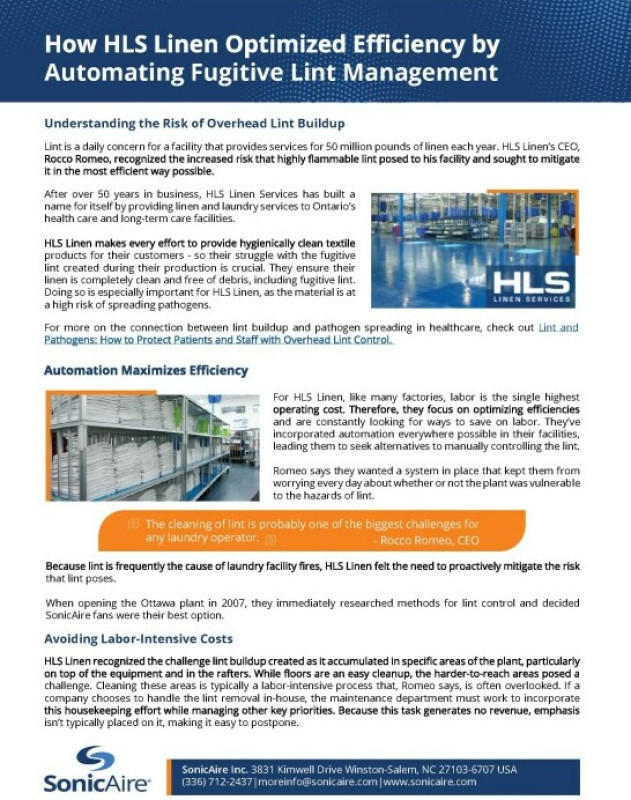

Lint is a daily concern for a facility that provides services for 50 million pounds of linen each year. HLS Linen’s CEO, Rocco Romeo, recognized the increased risk that highly flammable lint posed to his facility and sought to mitigate it in the most efficient way possible.

After over 50 years in business, HLS Linen Services has built a name for itself by providing linen and laundry services to Ontario’s health care and long-term care facilities.

HLS Linen makes every effort to provide hygienically clean textile products for their customers – so their struggle with the fugitive lint created during their production is crucial. They ensure their linen is completely clean and free of debris, including fugitive lint. Doing so is especially important for HLS Linen, as the material is at a high risk of spreading pathogens.

For more on the connection between lint buildup and pathogen spreading in healthcare, check out Lint and Pathogens: How to Protect Patients and Staff with Overhead Lint Control.

HLS Linen recognized the challenge lint buildup created as it accumulated in specific areas of the plant, particularly on top of the equipment and in the rafters. While floors are an easy cleanup, the harder-to-reach areas posed a challenge. Cleaning these areas is typically a labor-intensive process that, Romeo says, is often overlooked. If a company chooses to handle the lint removal in-house, the maintenance department must work to incorporate this housekeeping effort while managing other key priorities. Because this task generates no revenue, emphasis isn’t typically placed on it, making it easy to postpone.

Transforming Dusty to Dust-Free

The Inspiring Journey of One Company

The Inspiring Journey of One Company

Wood dust was a concern for KATERRA from the very beginning. Although no longer in operation, KATERRA manufactured composite panels and cross-laminated timber (CLT). More specifically, they supply engineered floor and wall systems for office buildings with large commercial applications. In short, they created enormous sheets of paneling.

And that meant a lot of dust.

“We had huge dust issues. It was an open environment mill, so there were no partition walls in between processes. We had dust from the CNCs ending up on the front end of the factory and created additional clean-up hours for departments other than ours” explained Cory Frashefski, Manager of the panel processing portion of the facility.

The dust that Cory’s panel processing portion generated tended to stay in the air longer than other dust, creating poor air quality. Because the dust had a moisture content of 12% and lower, it was incredibly light, causing it to fall to the ground slower – like a feather. The working environment was unpleasant and potentially unsafe, with the light, dry dust lingering in the air. To mitigate this, they had to provide respirators for the employees working in the panel processing.

KATERRA heard of SonicAire through word of mouth. Other mills they’d come across had been clients, and with a quick search, they began their journey to a compliant and safe facility through the installation of SonicAire fans.

With SonicAire fans, KATERRA no longer accumulated wood dust in the rafters and was able to keep the dust contained to the section it belonged to. This containment led to a more amicable employee culture and a better working environment.

Combustible Dust Fans for Wood Pellets Applications

Greene Team Pellet Fuel Company

“When it comes to controlling combustible dust, the best practice in the pellet manufacturing industry is to contain it,” reports Andy Galis, Operations Manager at Greene Team Pellet Fuel Company, “but it’s impossible to catch it all.”

“For all wood pellet manufacturers,” explains Galis, “the number one challenge is controlling combustible dust, especially the dry powder-like dust. Despite our best efforts to contain the dust, it still becomes airborne—and that is where the issue is.”

Galis explains, “Even if we contained 99.99% of the dry dust going into the pellet mill, that would still lead to over 130 pounds of dry dust becoming airborne per week from each pellet mill. And this dust is highly flammable. Our dust typically exits the dryer around 10% H2O. It’s the smallest pieces that escape suction, and these are typically around 3% H2O, making them even more dangerous. Once the dust is that dry, we treat it like gasoline.”

“If an explosion were to happen, dust gets rattled off the horizontal surfaces and then could potentially fuel a secondary (typically more dangerous) explosion. The way to prevent this is with SonicAire fans. We installed four in our facility, and we’re amazed at how clean the overhead areas are staying. There is practically zero dust in the rafters. We couldn’t be happier with the performance of the SonicAire fans. It makes our plant much safer.”

Combustible Dust Fans for Plastics Applications

Continental Structural Plastics

Continental Structural Plastics

Dedicated to best practices in all facets of its business, Continental Structural Plastics (CSP) was determined to find the best solution for eliminating combustible dust, which can lead to fire and explosion events in plastics manufacturing environments.

“The main challenge is when the dust is out of reach,” notes Tracy Gray, Plant Manager of the Lenoir, NC facility. “We had a housekeeping program in place, but our ceilings reach heights of 45 feet, and our molding presses are more than 20 feet tall.” When dust accumulates in these areas, cleaning isn’t a simple process.

“We had to have a crew come in and physically wipe down the presses,” explains Gray. “They had to harness in and then work through cleaning each of the 15 presses, wearing eye protection and safety gloves. We also had to schedule down-shifts to free up the presses for this cleaning, and then work overtime in advance to prepare for lost production time.”

CSP installed SonicAire industrial dust control fans in the Lenoir plant. The results have provided a trifecta of benefits for CSP.

SonicAire’s proprietary technology provides cost reduction and convenience. The fans work while the plant is in operation, to maintain the cleanliness of the plant. Gray reports, “We run the fans 24/7, and they have kept the overhead areas constantly clean.”

“As an added benefit,” notes Gray, “the fans circulate the air so the exhaust system can pull air out of the roof more effectively. This has noticeably reduced the ambient temperature in the plant. This is a nice benefit to help keep our operators more comfortable.”

Combustible Dust Fans for Bulk Powder

Chemical Manufacturer

Chemical Manufacturer

As an industry leader in chemical manufacturing, the corporation is dedicated to delivering sustainable solutions. To enhance the cleanliness, safety and efficiency of their plastics additives unit, they turned to SonicAire.

The production manager explains, “We installed two SonicAire industrial dust control fans in our charging station room. Here, we feed 2000 to 3000 kg of powder into our machines each hour. With this constant movement, powder particles inevitably accumulate in overhead areas. And with 25’ ceilings, this area was challenging to clean.”

Before SonicAire Fans: Combustible Dust Accumulation and High Cost

Before the SonicAire fans transformed their process, the plant spent $30K each year on manual housekeeping for this space. “To reach the overhead beams, we hired a pressure washing company,” the production manager reports. “They had to wash everything down manually, then use a vacuum truck to clear the floor. This required two to three days of down time on top of the cost of the service, and we had to do this three times each year to keep up with the dust accumulation.”

“All of our powder is white,” he notes. “Before the dust control fans were installed, you could see where the powder accumulated. Now, you don’t see any build-up. You can definitely see the difference.”

This clean atmosphere ensures OSHA compliance. It also offers a better first impression for the visitors who come through the facility.

The manager says, “We follow the standard of ‘dime-thickness’ accumulation, and our powder dust quickly built up to this level. Without the SonicAire fans, the combustible dust could get to that point or above before we could get the contractor here to clean it. Now, with the fans functioning, they keep us within compliance.”

Combustible Dust Fans for Wood Cabinets and Furniture Applications

Kent Moore Cabinets

Prior to SonicAire fans, Kent Moore Cabinets had a serious problem with dust accumulation. VP of Operations Jack Moreno reports, “It looked like the building had been vacant, with all the dust webs present.”

“We were cleaning by hand but had to find the time and manpower. Since installation, we’ve seen a drastic improvement.” He adds, “Visitors to the plant are amazed at how clean we have that area.”

“And I think it helps employees, their frame of mind, to say they’re working in a nice, clean environment in a woodworking facility.”

Would he recommend SonicAire for other facilities? Yes. Moreno says, “It’s unbelievable the amount of labor savings and other things that go along with it. It’s impressive. When you think about the man hours it takes to clean that facility and to get it clean like the SonicAire fans maintain it for you – you see the payback very quickly.”

Watson Wood Works

In 2013, Watson Wood Works received a surprise visit… from an OSHA inspector. At one point, Watson was part of an annual inspection program, but they hadn’t seen anyone in 10 years. With the lack of regular visits, some of their housekeeping had fallen behind.

According to Jesse Watson, President of Watson Wood Works, “It could have easily been a finable offense.” Instead, the OSHA inspector gave them time to make corrective actions regarding the dust. Watson’s first inclination was to hire a specialized cleaning crew. But

the quote was prohibitively expensive. “It would have cost $40,000 per cleaning, and we’d need bi-annual visits. Add that to the lost production, and it would have cost us well over $200,000 per year in fees and lost revenue. It just wasn’t sustainable.”

Combustible Dust Fans for Plywood Manufacturing

Columbia Forest Products

“At first, we tried a large vacuum system,” says Wakefield. “But after a while, we knew we needed something more efficient. We learned about SonicAire and decided to try their industrial dust control fan system.”

“The fans drastically reduced the labor we were using for cleaning,” says Wakefield. “We no longer have to send trained workers on lifts into those areas every quarter. We don’t have to schedule weekends and overtime for workers to do all that prep work and cleaning. We don’t even have to wipe off the flat surfaces on top of the equipment anymore. The SonicAire fans have alleviated all of that.”

“From both a dollar standpoint and employee benefits, the SonicAire fans have been a big win,” Wakefield concludes.

Combustible Dust Fans for Commercial Laundry Applications

Commonwealth Linen Service

Commonwealth Linen Service

“Lint is the biggest carrier of pathogens in the laundry environment,” explains Jim Buchbinder, director of Commonwealth Linen. “So, if lint isn’t present for the pathogens to attach to, then you’ve eliminated a big problem in your plant.”

To maintain top hygiene protocols for their 42,000-square-foot facility, Commonwealth Linen has installed SonicAire industrial dust control fans.

Buchbinder reports, “Any laundry that becomes accredited by the Healthcare Laundry Accreditation Council (HLAC) needs to have a processing area environment that is free from lint. We find that SonicAire fans really help us maintain that environment, making it a lot easier for my team to keep the plant clean and free of lint.”

“Keeping these areas clean was a particular challenge in this facility, because we have an HVAC system,” continued Buchbinder. “This helps us maintain better air quality, but we don’t have exhaust fans on the clean side of our plant. Without these, all of the lint tends to settle down on the equipment and rafters. There’s no place for it to escape.”

Buchbinder notes an added benefit from the SonicAire fans. As part of their marketing efforts, Commonwealth Linen Services offers facility tours to current and potential clients, and the indoor air quality is remarkable. Buchbinder reports that he hears great feedback about the absence of lint in their plant. “I constantly get comments,” he says. “It’s good for our employees, good for our customers and good for business.”

How a Food Ingredient Production Facility Eliminated a Dust Cleaning Nightmare

An Unreasonable Amount of Clean-Up Time

In a sweltering Georgia factory, employees had to clean up combustible dust for two hours every day and manually clean the facility’s dust build-up with air hoses and brooms. This made their working environment even more uncomfortable on top of the oppressive heat.

You can’t eliminate all ignition sources, and even static from your clothing can be disastrous. Blown-down dust accumulation is prohibited except within very specific conditions and only after specific precautions have been taken.

SonicAire fans were installed to clean dust build up in their facility and the change has been phenomenal, as the company no longer has to spend time cleaning up and no longer has to worry about dust explosions.”Since we’ve installed the fans, it’s been phenomenal – we don’t spend any time cleaning up, and we don’t have to worry about dust explosions or anything like that.”

Combustible Dust Fans for Boat Builders

Viking Yachts

Viking Yachts

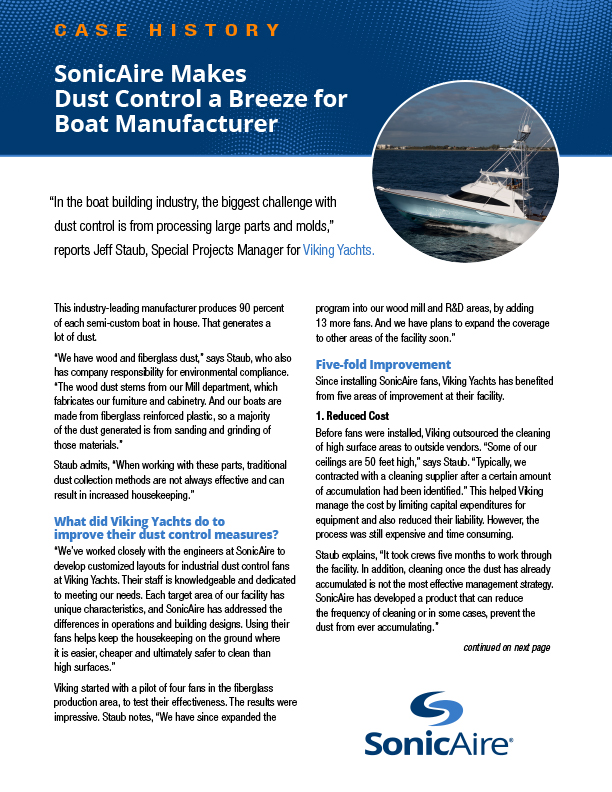

“In the boat building industry, the biggest challenge with dust control is from processing large parts and molds,” reports Jeff Staub, Special Projects Manager for Viking Yachts.

This industry-leading manufacturer produces 90 percent of each semi-custom boat in house. That generates a lot of dust.

“We have wood and fiberglass dust,” says Staub, who also has company responsibility for environmental compliance. “The wood dust stems from our Mill department, which fabricates our furniture and cabinetry. And our boats are made from fiberglass reinforced plastic, so a majority of the dust generated is from sanding and grinding of those materials.”

Staub admits, “When working with these parts, traditional dust collection methods are not always effective and can result in increased housekeeping.”

What did Viking Yachts do to improve their dust control measures?

“We’ve worked closely with the engineers at SonicAire to develop customized layouts for industrial dust control fans at Viking Yachts. Their staff is knowledgeable and dedicated to meeting our needs. Each target area of our facility has unique characteristics, and SonicAire has addressed the differences in operations and building designs. Using their fans helps keep the housekeeping on the ground where it is easier, cheaper and ultimately safer to clean than high surfaces.”

Since installing SonicAire fans, Viking Yachts has benefited from five areas of improvement at their facility.

- Reduced Cost

- Reduced Downtime

- Reduced Risk

- Increased Morale

- Increased Compliance

It didn’t take long for Viking Yachts to start reaping the benefits of SonicAire fans. Staub reports, “With SonicAire fans, it is immediately noticeable that high surfaces—where dust previously accumulated quickly—are clean.”

Success Stories

Combustible Dust Fans for Wood Pellets Applications

Greene Team Pellet Fuel Company

“When it comes to controlling combustible dust, the best practice in the pellet manufacturing industry is to contain it,” reports Andy Galis, Operations Manager at Greene Team Pellet Fuel Company, “but it’s impossible to catch it all.”

“For all wood pellet manufacturers,” explains Galis, “the number one challenge is controlling combustible dust, especially the dry powder-like dust. Despite our best efforts to contain the dust, it still becomes airborne—and that is where the issue is.”

Galis explains, “Even if we contained 99.99% of the dry dust going into the pellet mill, that would still lead to over 130 pounds of dry dust becoming airborne per week from each pellet mill. And this dust is highly flammable. Our dust typically exits the dryer around 10% H2O. It’s the smallest pieces that escape suction, and these are typically around 3% H2O, making them even more dangerous. Once the dust is that dry, we treat it like gasoline.”

“If an explosion were to happen, dust gets rattled off the horizontal surfaces and then could potentially fuel a secondary (typically more dangerous) explosion. The way to prevent this is with SonicAire fans. We installed four in our facility, and we’re amazed at how clean the overhead areas are staying. There is practically zero dust in the rafters. We couldn’t be happier with the performance of the SonicAire fans. It makes our plant much safer.”

Combustible Dust Fans for Plastics Applications

Continental Structural Plastics

Dedicated to best practices in all facets of its business, Continental Structural Plastics (CSP) was determined to find the best solution for eliminating combustible dust, which can lead to fire and explosion events in plastics manufacturing environments.

“The main challenge is when the dust is out of reach,” notes Tracy Gray, Plant Manager of the Lenoir, NC facility. “We had a housekeeping program in place, but our ceilings reach heights of 45 feet, and our molding presses are more than 20 feet tall.” When dust accumulates in these areas, cleaning isn’t a simple process.

“We had to have a crew come in and physically wipe down the presses,” explains Gray. “They had to harness in and then work through cleaning each of the 15 presses, wearing eye protection and safety gloves. We also had to schedule down-shifts to free up the presses for this cleaning, and then work overtime in advance to prepare for lost production time.”

CSP installed SonicAire industrial dust control fans in the Lenoir plant. The results have provided a trifecta of benefits for CSP.

SonicAire’s proprietary technology provides cost reduction and convenience. The fans work while the plant is in operation, to maintain the cleanliness of the plant. Gray reports, “We run the fans 24/7, and they have kept the overhead areas constantly clean.”

“As an added benefit,” notes Gray, “the fans circulate the air so the exhaust system can pull air out of the roof more effectively. This has noticeably reduced the ambient temperature in the plant. This is a nice benefit to help keep our operators more comfortable.”

Combustible Dust Fans for Wood Cabinets and Furniture Applications

Kent Moore Cabinets

Prior to SonicAire fans, Kent Moore Cabinets had a serious problem with dust accumulation. VP of Operations Jack Moreno reports, “It looked like the building had been vacant, with all the dust webs present.”

“We were cleaning by hand but had to find the time and manpower. Since installation, we’ve seen a drastic improvement.” He adds, “Visitors to the plant are amazed at how clean we have that area.”

“And I think it helps employees, their frame of mind, to say they’re working in a nice, clean environment in a woodworking facility.”

Moreno admits to trying an experiment: he temporarily turned off the fans after installation. He notes, “I was amazed at how quickly the dust accumulated.”

Would he recommend SonicAire for other facilities? Yes. Moreno says, “It’s unbelievable the amount of labor savings and other things that go along with it. It’s impressive. When you think about the man hours it takes to clean that facility and to get it clean like the SonicAire fans maintain it for you – you see the payback very quickly.”

Combustible Dust Fans for Plywood Manufacturing

Columbia Forest Products

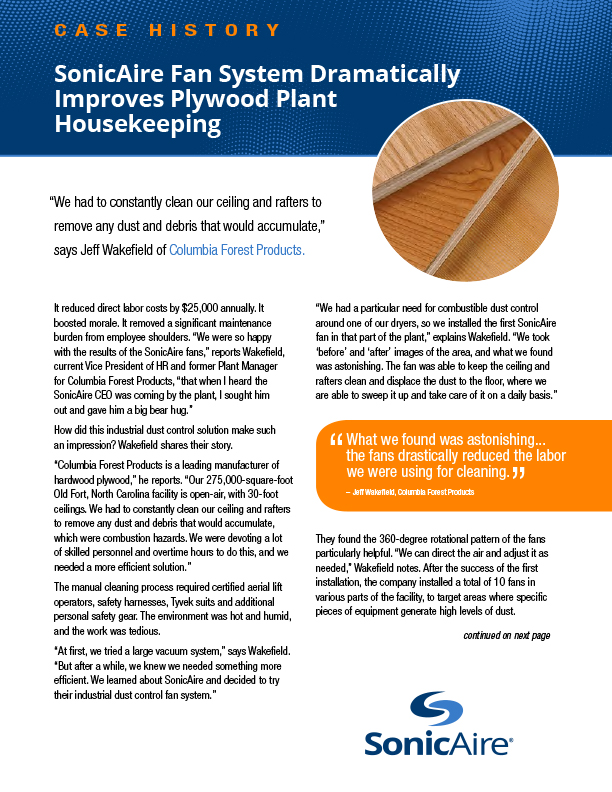

“Columbia Forest Products is a leading manufacturer of hardwood plywood,” reports Jeff Wakefield, current Vice President of HR and former Plant Manager. “Our 275,000-square-foot Old Fort, North Carolina facility is open-air, with 30-foot ceilings. We had to constantly clean our ceiling and rafters to remove any dust and debris that would accumulate, which were combustion hazards.”

“At first, we tried a large vacuum system,” says Wakefield. “But after a while, we knew we needed something more efficient. We learned about SonicAire and decided to try their industrial dust control fan system.”

“The fans drastically reduced the labor we were using for cleaning,” says Wakefield. “We no longer have to send trained workers on lifts into those areas every quarter. We don’t have to schedule weekends and overtime for workers to do all that prep work and cleaning. We don’t even have to wipe off the flat surfaces on top of the equipment anymore. The SonicAire fans have alleviated all of that.”

This reduction in workload not only saves resources, it has been a big morale boost for employees. “Our workers were very happy to no longer have to bear this cleaning burden,” Wakefield continues.

“From both a dollar standpoint and employee benefits, the SonicAire fans have been a big win,” Wakefield concludes.

Combustible Dust Fans for Commercial Laundry Applications

Commonwealth Linen Service

“Lint is the biggest carrier of pathogens in the laundry environment,” explains Jim Buchbinder, director of Commonwealth Linen. “So, if lint isn’t present for the pathogens to attach to, then you’ve eliminated a big problem in your plant.”

To maintain top hygiene protocols for their 42,000-square-foot facility, Commonwealth Linen has installed SonicAire industrial dust control fans.

Buchbinder reports, “Any laundry that becomes accredited by the Healthcare Laundry Accreditation Council (HLAC) needs to have a processing area environment that is free from lint. We find that SonicAire fans really help us maintain that environment, making it a lot easier for my team to keep the plant clean and free of lint.”

“Keeping these areas clean was a particular challenge in this facility, because we have an HVAC system,” continued Buchbinder. “This helps us maintain better air quality, but we don’t have exhaust fans on the clean side of our plant. Without these, all of the lint tends to settle down on the equipment and rafters. There’s no place for it to escape.”

Lint that gets trapped in overhead areas accumulates and poses a fire hazard to the facility, supporting fire spread if the lint ignites.

Buchbinder notes an added benefit from the SonicAire fans. As part of their marketing efforts, Commonwealth Linen Services offers facility tours to current and potential clients, and the indoor air quality is remarkable. Buchbinder reports that he hears great feedback about the absence of lint in their plant. “I constantly get comments,” he says. “It’s good for our employees, good for our customers and good for business.”

Combustible Dust Fans for Boat Builders

Viking Yachts

“In the boat building industry, the biggest challenge with dust control is from processing large parts and molds,” reports Jeff Staub, Special Projects Manager for Viking Yachts.

This industry-leading manufacturer produces 90 percent of each semi-custom boat in house. That generates a lot of dust.

“We have wood and fiberglass dust,” says Staub, who also has company responsibility for environmental compliance. “The wood dust stems from our Mill department, which fabricates our furniture and cabinetry. And our boats are made from fiberglass reinforced plastic, so a majority of the dust generated is from sanding and grinding of those materials.”

Staub admits, “When working with these parts, traditional dust collection methods are not always effective and can result in increased housekeeping.”

What did Viking Yachts do to improve their dust control measures?

“We’ve worked closely with the engineers at SonicAire to develop customized layouts for industrial dust control fans at Viking Yachts. Their staff is knowledgeable and dedicated to meeting our needs. Each target area of our facility has unique characteristics, and SonicAire has addressed the differences in operations and building designs. Using their fans helps keep the housekeeping on the ground where it is easier, cheaper and ultimately safer to clean than high surfaces.”

Since installing SonicAire fans, Viking Yachts has benefited from five areas of improvement at their facility.

- Reduced Cost

- Reduced Downtime

- Reduced Risk

- Increased Morale

- Increased Compliance

It didn’t take long for Viking Yachts to start reaping the benefits of SonicAire fans. Staub reports, “With SonicAire fans, it is immediately noticeable that high surfaces—where dust previously accumulated quickly—are clean.”

Understanding the Risk of Overhead Lint Buildup

Understanding the Risk of Overhead Lint Buildup

The Inspiring Journey of One Company

The Inspiring Journey of One Company

Continental Structural Plastics

Continental Structural Plastics

Chemical Manufacturer

Chemical Manufacturer

Commonwealth Linen Service

Commonwealth Linen Service

Viking Yachts

Viking Yachts