What are the Hazards of Plastic Dust?

The development of plastic in 1907 transformed our entire society. It’s become an industry that surrounds us in virtually every setting. Plastic molding, powders, blending, plastics extruding, forming, and finishing all create the products that shape our world. Not only do plastics make up large components of the leading automotive, electronics, and packaging industries, but they also play some role in virtually all manufacturing. In short, plastics have become integral to our society and economy.

The development of plastic in 1907 transformed our entire society. It’s become an industry that surrounds us in virtually every setting. Plastic molding, powders, blending, plastics extruding, forming, and finishing all create the products that shape our world. Not only do plastics make up large components of the leading automotive, electronics, and packaging industries, but they also play some role in virtually all manufacturing. In short, plastics have become integral to our society and economy.

With this significant contribution to our everyday lives came a significant byproduct: combustible dust. As manufacturers, they utilize blend powders and trim/shape materials, these processes inevitably create dust. High volumes of plastic production equals high volumes of dust. As this dust accumulates, it poses a fire and explosion hazard.

Plastic dust can be particularly dangerous because it may generate volatile gas, making even proximity to the fire a hazard. This means even being in close proximity to a fire is a hazard. Add in the confinement element of the combustion pentagon, and now you have an explosion and toxic fumes. Remember that plastic dust is combustible, meaning you may not have time for a response. The best way to handle combustible plastic dust is to never let it accumulate in your facility.

Successful Dust Control in Plastic Facilities

At The AZEK Company’s Corey Street Plant in Scranton, PA, operations run 24 hours a day, 365 days a year. With continuous blending operations, PVC dust ended up everywhere. The company’s insurer was concerned about the quantity of dust and considered raising rates due to the liability of a combustion event.

Click the video below to hear the case study.

How Can Your Facility Manage Combustible Plastic Dust?

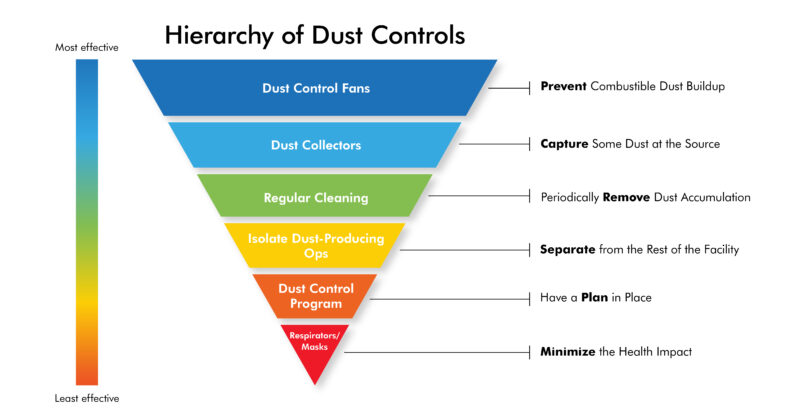

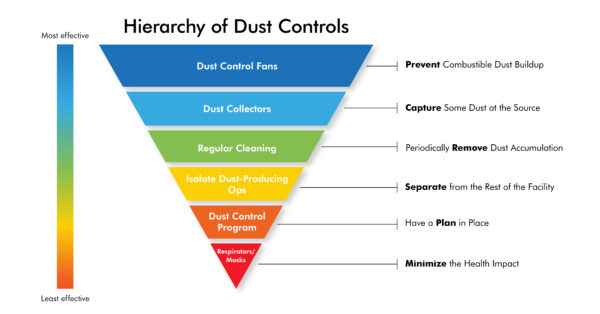

When it comes to fugitive dust, you have a few options. With plastic dust, however, those options depend heavily on safety. You can remove the dust after it accumulates with blow down methods, like pressurized air. Of course, that’s pretty difficult to do safely and requires a strict (and often impossible) set of requirements to be within regulations. (See the National Fire Protection Association’s Standard for the Prevention of Fire and Dust Explosions from the Manufacturing, Processing, and Handling of Combustible Particulate Solids NFPA 654, section 8.2.2.4 for the details on requirements and whether or not it’s even a possibility for your facility.)

You could also elect to clean the dust after it builds up. This option requires a significant workforce and regular maintenance. You should note you may need to shut down your facility’s production while you perform these cleanings, and pulling employees away from their regular tasks to complete it is commonly met with a drop in employee morale. You could hire an external cleaning crew, but that expense is pretty steep, and you’ll need to pay it frequently.

The final option is prevention. To keep dust from ever accumulating is the one that keeps your facility safe and compliant with dust management every second of every day. There isn’t ever a time when your facility is at risk for a combustible dust event, and a surprise inspection will never catch you with bad dust housekeeping practices.

No one wants a fire, but plastic dust has an added danger level that requires you to maintain constant diligence in preventing dust accumulation. With the possible toxic gasses released in the event of a fire melting the plastic dust, extra care must be taken to prevent fires from ever occurring. This need makes it especially appealing to, rather than clean up the dust regularly, prevent it from ever accumulating.

Dust control fans from SonicAire make the prevention of dust build up easy.

For more on your dust control options’ effectiveness, check out Ranking Six Combustible Dust Control Measures From Least to Most Effective.

What Does Successful Dust Control in Plastic Facilities Look Like?

Despite one plastics manufacturing plant’s non-highly combustible dust, concerns from both the insurance company and OSHA prompted proactive measures. Previously, cleaning companies were hired before inspections to remove dust buildup. However, this approach was temporary, and dust levels would rise again after inspections. Introducing SonicAire fans resolved this issue by continuously preventing dust buildup. This not only maintained a cleaner environment but also prevented potential insurance rate hikes due to dust levels. Thomas and his colleagues found the change positively impactful, creating a safer and more enjoyable work environment with consistent air quality and visibility. The SonicAire fans effectively addressed dust management concerns, providing long-term benefits for the company’s operations and employee satisfaction.

Click the video below to see how SonicAire fans completely changed the environment at one plant.

How Can Your Facility Manage Combustible Dust in the Plastics Industry?

When it comes to fugitive combustible dust, you have a few options. With plastic dust, however, choosing the right solution should be driven by safety. You can remove the dust after it accumulates with blowdown methods, like pressurized air. Of course, that’s difficult to do safely and requires a strict (and often impossible) set of requirements to be within regulations. (See the National Fire Protection Association’s Standard for the Prevention of Fire and Dust Explosions from the Manufacturing, Processing, and Handling of Combustible Particulate Solids NFPA 654, section 8.2.2.4 for the details on requirements and whether it’s even a possibility for your facility).

You could also elect to manually vacuum the dust after it builds up. This option requires a significant workforce and a cyclical cleaning schedule. You may need to shut down your facility’s production while you perform these cleanings. And pulling employees away from their regular tasks hurts your bottom line and may lower employee morale. You could hire an external cleaning crew, but that expense is steep, and you’ll need to keep paying for it, over and over.

The final option is prevention. Taking a proactive approach to combustible dust keeps your facility safe and compliant with dust management every second of every day. You won’t need to stress over the risk of a fire or explosion, and a surprise inspection will never catch you off guard.

No one wants a fire, but plastic dust has an added danger level that requires you to maintain constant diligence in preventing dust accumulation. With possible toxic gasses released in the event of a fire melting the plastic dust, extra care must be taken to prevent fires from ever occurring. Imagine being able to prevent dust from ever accumulating, rather than having to clean it up regularly. This proactive, automated approach is attainable by adding dust control fans to your dust abatement system.

Dust control fans from SonicAire make the prevention of dust build up easy.

For more on your dust control solutions’ effectiveness, check out Ranking Six Combustible Dust Control Measures From Least to Most Effective.

What is a Dust Hazard Analysis?

With years of experience in testing and consulting on combustible dust hazards and nearly a century of operations focusing on safety, DEKRA is an excellent all-around resource for your specialized demands.

Click the video below to watch this conversation and discover the best next steps once you’ve completed your DHA.

How Do SonicAire Fans Prevent Dust Buildup?

SonicAire’s proprietary technology combines two methods to control dust flow.

High-Velocity Airflow

SonicAire’s specialized fans use high-velocity airflow to clean overhead areas. This ultra-powerful airflow effectively prevents the accumulation of combustible dust on overhead structures and provides better dust control for your wood production facility. The technology behind these fans will automate your dust management, operating in the background without any extra thought from you or your employees.

Thermal-Current Control

Typical airflow involves warm air currents naturally rising and lifting dust to overhead structures, where it accumulates quickly. SonicAire’s industrial dust control fans prevent these naturally occurring upward thermal currents from holding dust in the air in the first place. Our fans create an air barrier below the overhead structures so the dust doesn’t rise above them and settle on top. When dust isn’t given free-reign in a facility the air quality will also inevitably improve.

With these unique and efficient approaches, our specialists design a customized plan, especially for your facility, to ensure that the dust accumulation in your facility is kept at a safe, minimal level.

SonicAire can mitigate the danger of combustible dust in your facility; reach out to speak to one of our specialists to get started. We’ll guide you through exactly how to make your workspace as safe as possible from dangerous buildup, while also saving you time and money from manual cleaning, insurance costs, and OSHA fines.

Additional Resources

Learn more about how we helped companies like yours find solutions to their dust problems.

Complimentary Dust Management Plan with ROI Analysis

Our analysis will also show you the expected Return on Investment, including equipment investment, estimated annual savings and cumulative cashflow benefit.

Get started by contacting us today for your custom facility review, ROI analysis and fan technology proposal.

Plastics Industry Overview

Plastic is one of the largest manufacturing industries in the United States, supplying components for a wide range of production. The industry employs nearly one million people and generates $451 billion yearly in shipments.

Demand for plastic components continues to grow, particularly in the automotive industry, where plastics facilitate fuel savings and weight reduction. Plastics are also highly sought after for industrial machinery and consumer goods. Due to plastic’s versatility and durability, the industry is also gaining ground in the medical, military, and construction sectors.

Plastics manufacturing covers a broad spectrum of processes, including:

- Thermoforming

- Transfer Molding

- Reaction Injection Molding

- Compression Molding

- Rotational Molding

- Extrusion

- Vacuum Forming

- Polymer Casting

- CNC Machining

- Plastics Recycling

- Additive Manufacturing (3D Printing)

- Blending

- Bulk Powder

Get Your Complimentary Dust Management Plan with ROI Analysis

Our analysis will also show you the expected Return on Investment, including equipment investment, estimated annual savings and cumulative cashflow benefit.

Get started by contacting us today for your custom facility review, ROI analysis and fan technology proposal.