The Hazards of Recycling Dust

The recycling industry has grown significantly over the years, driven by concerns about environmental sustainability and the need to conserve natural resources. The industry encompasses a wide range of materials, including paper, plastics, metals, and electronics.

One of the biggest challenges associated with recycling is the generation of dust. Dust can be created through several processes in the recycling facility. Shredding, crushing, and sorting waste materials creates fine particles that can become airborne and settle on surfaces throughout the facility. If not properly managed, this dust can accumulate and pose a hazard to workers and equipment.

How Does Recycling Dust Combust?

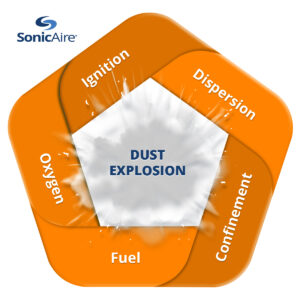

Recycling dust can combust when several factors align.

- Fuel: Combustible dust is the fuel component of the dust explosion pentagon. This can include any fine particulate material capable of burning, such as paper, plastic, metal, or organic matter. A recycling facility often has all these fuel sources.

- Oxygen: Oxygen is necessary to sustain combustion and is present in the air around us. In a confined space, oxygen levels can increase, making the environment more conducive to combustion.

- Ignition: Ignition can come from various sources, such as sparks, hot surfaces, electrical equipment, or static electricity. Ignition is what causes the fuel to ignite and start the explosion.

- Confinement: Confinement refers to the space in which the dust is contained. When dust is confined in a space, the pressure and temperature can increase, making it more likely to ignite and explode.

- Dispersion: Dispersion refers to the movement of dust particles through the air. When dust becomes airborne, it can form a cloud more susceptible to ignition and explosion.

When these conditions are met, the dust cloud can ignite and rapidly propagate an explosion throughout the facility. By addressing one or more of the components of the pentagon, it is possible to reduce the risk of a dust explosion and keep workers and equipment safe.

How Do SonicAire Fans Prevent Dust Buildup?

High-Velocity Airflow

SonicAire’s specialized fans use high-velocity airflow to clean overhead areas. This ultra-powerful airflow effectively prevents the accumulation of combustible dust on overhead structures and provides better dust control for your recycling facility. Your business will also enjoy the benefits of a facility compliant on dust.

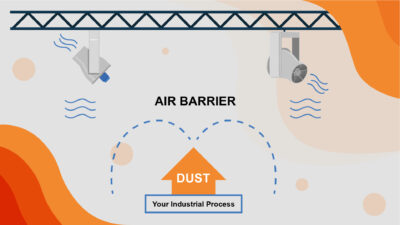

Thermal-Current Control

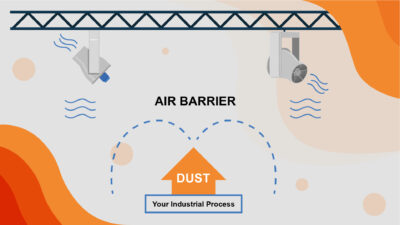

Typical airflow involves warm air currents naturally rising and lifting dust to overhead structures, where it accumulates quickly. SonicAire’s industrial dust control fans prevent these naturally occurring upward thermal currents from holding dust in the air in the first place. Our fans create an air barrier below the overhead structures so the dust doesn’t rise above them and settle on top.

BarrierAire

Using these two unique and efficient approaches, and with the help of our specialists, you can be assured that lint accumulation in your facility will be kept at a safe, minimal level.

Contact us today to speak to one of our trained specialists about how SonicAire can mitigate the danger of dust and lint in your facility. We would love to show you exactly how to make your workspace as safe as possible from dangerous buildup as well as save you time and money from having to do manual clean-up.

How Do SonicAire Fans Prevent Dust Buildup?

High-Velocity Airflow

SonicAire’s specialized fans use high-velocity airflow to clean overhead areas. This ultra-powerful airflow effectively prevents the accumulation of combustible dust on overhead structures and provides better dust control for your recycling facility. Your business will also enjoy the benefits of a facility compliant on dust.

Thermal-Current Control

Typical airflow involves warm air currents naturally rising and lifting dust to overhead structures, where it accumulates quickly. SonicAire’s industrial dust control fans prevent these naturally occurring upward thermal currents from holding dust in the air in the first place. Our fans create an air barrier below the overhead structures so the dust doesn’t rise above them and settle on top.

BarrierAire

Using these two unique and efficient approaches, and with the help of our specialists, you can be assured that lint accumulation in your facility will be kept at a safe, minimal level.

Contact us today to speak to one of our trained specialists about how SonicAire can mitigate the danger of dust and lint in your facility. We would love to show you exactly how to make your workspace as safe as possible from dangerous buildup as well as save you time and money from having to do manual clean-up.

What To Expect When You Work With SonicAire

After almost 20 years in business, we’ve figured out what works and what doesn’t regarding dust control. We’ve boiled it down into four simple steps: Discover, Design, Deliver, and Your Dust is Done. Now you may ask yourself, how do those four steps work when protecting your facility from fugitive dust?

Here’s How Easy We’ll Make Fugitive Dust Management in Your Facility

DISCOVER

We’ll identify your biggest dust control challenges.

DESIGN

We’ll develop an engineered system specifically for your facility.

DELIVER

Your fans can be installed by you or a qualified contractor.

DUST IS DONE

You’ll know you’re protected from future dust accumulation.

To determine the right fan system for your facility, contact one of our Dust Control Experts.

Proven Process

To learn more about our proven process, check out the following videos:

Reduce Overtime and Maintain Compliance in your Recycling Facility

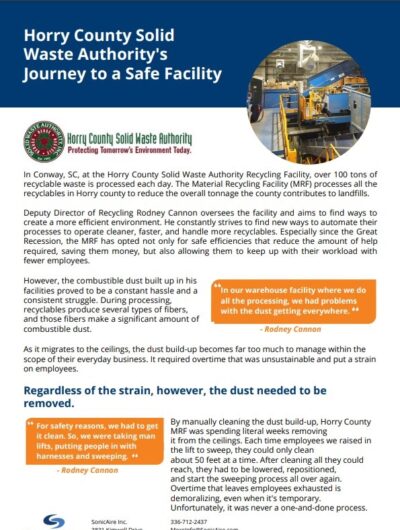

The Horry County Material Recycling Facility in South Carolina faced significant challenges related to dust accumulation and the risk of a potential dust explosion. To mitigate this risk, they turned to SonicAire dust control fans.

In the video below, you’ll hear from Rodney Cannon, Deputy Director of Recycling, on how SonicAire’s dust control fans were implemented at the facility and their impact on reducing dust accumulation and mitigating the risk of a dust explosion

Dust Regulation in the Recycling Industry

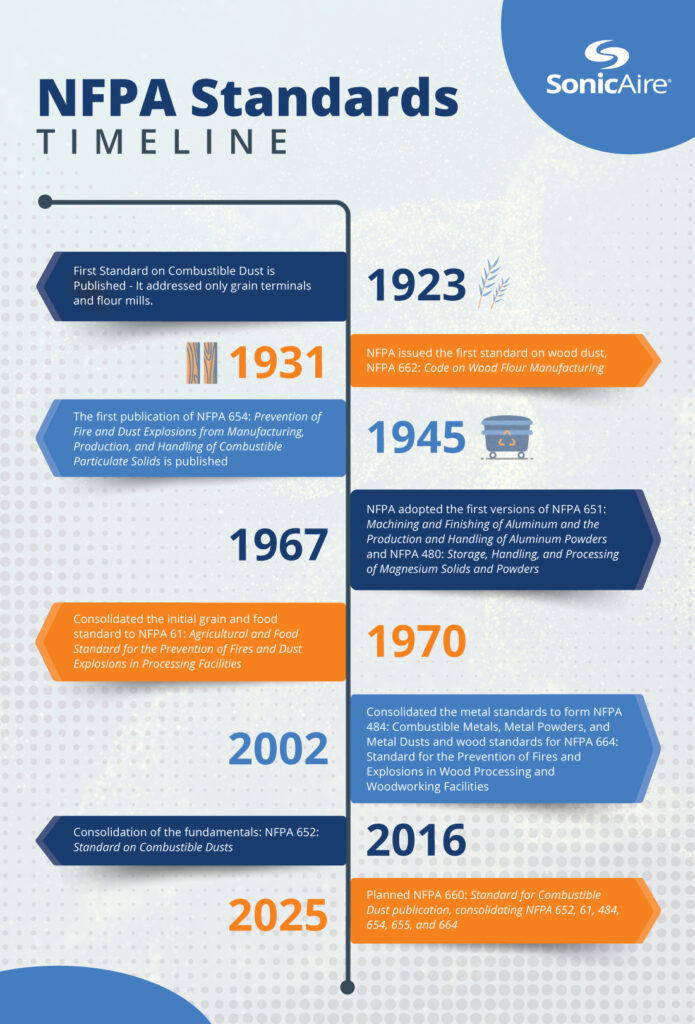

Can you believe it’s been 100 years since the National Fire Prevention Association (NFPA) published its first standard on combustible dust? That’s a century of making recycling facilities safer and preventing dust-related incidents!

Check out the timeline on combustible dust standards from their start – it’s pretty interesting to see how far we’ve come.

Recycling facilities play a vital role in managing combustible dust, and at SonicAire, we understand its significance firsthand. That’s why we’ve developed patented fan technology that uses non-impacting, non-clogging nozzles to clean hard-to-reach surfaces and prevent the accumulation of all types of dust.

And the good news keeps coming! In 2025, a new comprehensive dust standard – NFPA 660, Standard for Combustible Dusts – is set to consolidate six existing NFPA dust standards into one document. This development represents a significant leap forward in our ongoing efforts to combat dust hazards and improve recycling facility safety.

Additional Resources

Learn more about how we helped companies like yours find solutions to their dust problems.

Get Your Complimentary Dust Management Plan with ROI Analysis

Our analysis will also show you the expected Return on Investment, including equipment investment, estimated annual savings and cumulative cashflow benefit.

Get started by contacting us today for your custom facility review, ROI analysis and fan technology proposal.