We hope you enjoyed the webinar, liked what you heard, and want to learn more about how SonicAire can help your business

Contact SonicAire today to speak to our professionals about removing harmful combustible dust from your facility. Click the link below to contact us.

Frequently Asked Questions

Plastics and Powder Bulk and Solids Industries

Plastics Industry Overview

Plastics is one of the largest manufacturing industries in the United States. It employs nearly 1 million people, supplies components for a wide range of production, and generates almost $451 billion in shipments per year.

The demand for plastics has never been greater and continues to grow, particularly in the automotive industry. Plastics are versatile and durable, making them highly sought after in many industries, such as industrial and consumer goods and the medical, military and construction sectors. Suffice to say, plastics are present in almost every facet of our lives and will continue to be for the foreseeable future.

Powder and Bulk Solids Industry

Another massive industry also involved with plastics is the Powder and Bulk Solids (PBS) industry. Established in 1983 PBS serves a variety of industries that process, handle, and package dry particulate matter, including plastics.

Here’s the Problem

Since plastics have become integral to our society and play a part in virtually all manufacturing, the production of plastics has dramatically increased. While the increase in production is a good thing, the combustible dust from trimming and shaping plastic components presents a significant challenge.

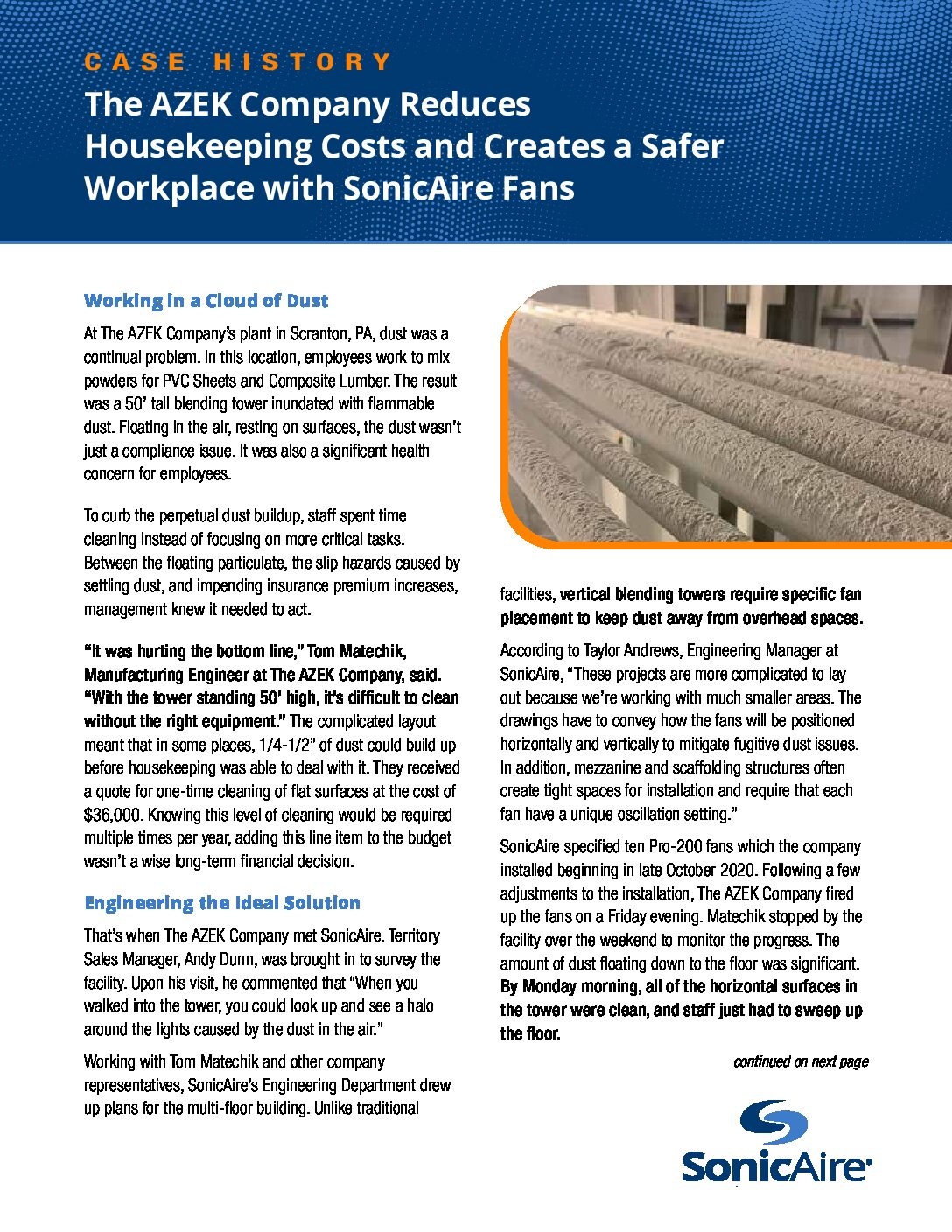

As the plastic dust accumulates, it poses a fire and explosion hazard. The dust heats up, melts and evaporates, generating volatile, flammable gas. Some plastics facilities use dust collection systems, but they don’t capture all the particles and fail to fully mitigate the risk of explosion or fire. In October 2019, a Connecticut-based manufacturer experienced an explosion in its dust collection unit, causing extensive damage.

Not only does uncollected plastic dust pose a significant hazard, but its collection and storage do as well.

So what is the solution?

How SonicAire Can Help

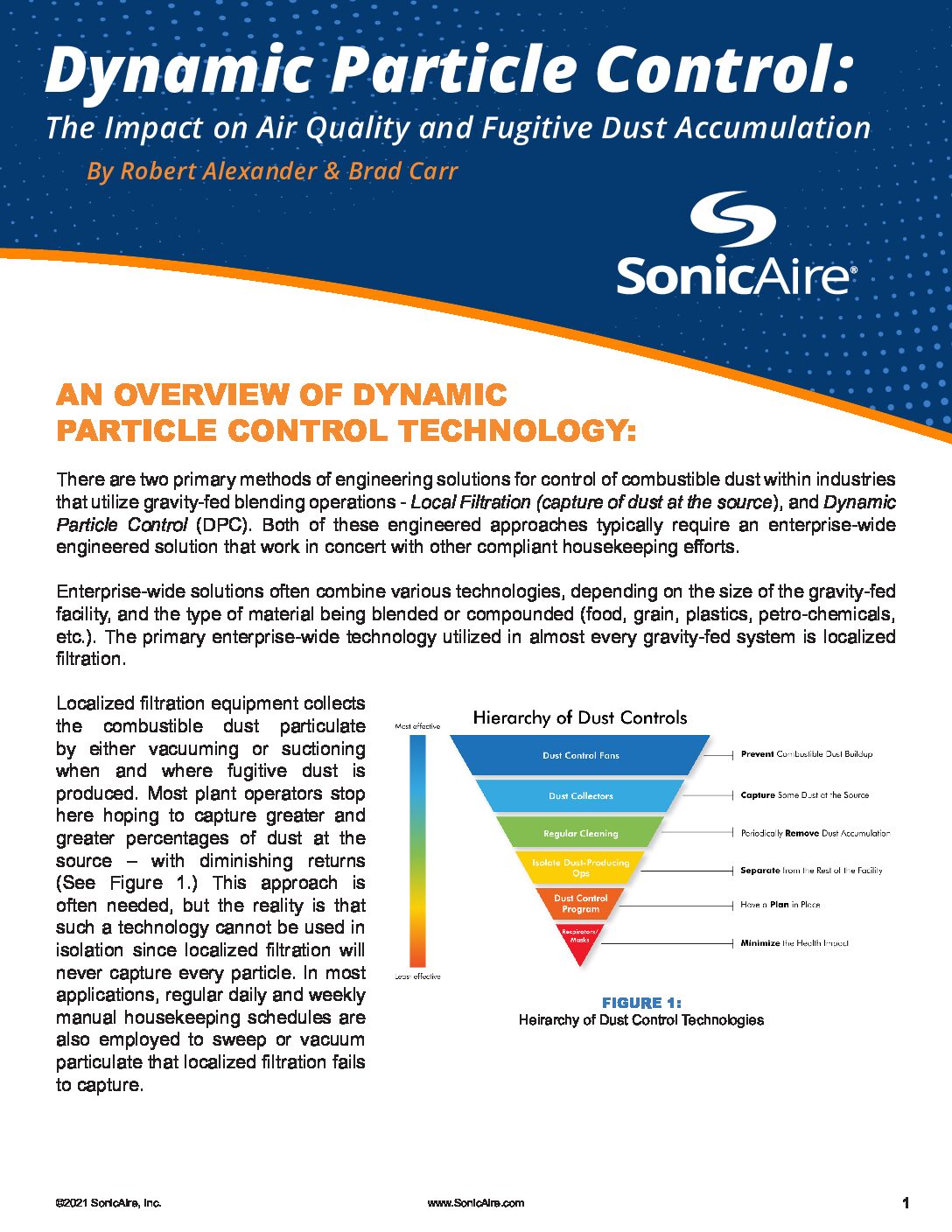

SonicAire utilizes precision dust-control technology, engineered specifically for the plastics industry. SonicAire’s industrial control fans proactively prevent combustible dust build-up, thereby maintaining a clean and safe environment in a cost-effective manner.

The SonicAire Solution

SonicAire’s proprietary technology combines two state-of-the-art methods, High-Velocity Airflow and Thermal-Current Control, to control dust flow.

High-Velocity Airflow

SonicAire’s specialized fans use high-velocity airflow to clean overhead areas. This ultra-powerful airflow effectively prevents the accumulation of combustible dust particles on overhead structures.

Thermal-Current Control

Typical airflow involves warm air currents naturally rising and lifting plastic particles to overhead structures where plastic dust accumulates quickly. SonicAire’s industrial dust control fans prevent these naturally occurring upward thermal currents from holding dust in the air in the first place. Our fans create an air barrier below the overhead structures, so the dust doesn’t rise above them and then settle on top.

Using these two unique and efficient technologies, and with the help of our specialists, you can be assured that flammable plastic dust accumulation in your facility will be kept at a safe, minimal level.

Contact us today to speak to one of our trained specialists about how SonicAire can mitigate the danger of explosive plastic dust in your facility. We would love to show you exactly how to make your workspace as safe as possible from dangerous plastic dust as well as save you time and money from having to do manual clean-up.

Complimentary Dust Management Plan with ROI Analysis

Our analysis will also show you the expected Return on Investment, including equipment investment, estimated annual savings and cumulative cashflow benefit.

Get started by contacting us today for your custom facility review, ROI analysis and fan technology proposal.

Complimentary Dust Management Plan with ROI Analysis

Our analysis will also show you the expected Return on Investment, including equipment investment, estimated annual savings and cumulative cashflow benefit.

Get started by contacting us today for your custom facility review, ROI analysis and fan technology proposal.