The Hazards of Wood Dust

The dust found in a woodworking facility gathers on every surface, and its build up can be extremely hazardous. Within this industry, numerous processes can generate enough dust to pose a hazard. The more obvious methods of sawing, planing, routing, and sanding make the list, but other processes, such as sawdust delivery and pellet creation, also add to dust deposits.

Advances in wood production haven’t made dust control any easier. High-efficiency machines create finer dust particles, and their increased production capabilities result in more dust overall. And unfortunately, even the most modern dust collection methods have a hard time keeping up high levels of dust production.

The challenge for wood product facilities is how to handle the accumulation of this combustible dust.

What You Need to Know About Wood Dust

- Wood Dust is Combustible. You probably already know that, sure. But here’s why: Because wood dust is so fine, each particle of dust has a huge surface area compared to its mass. Burning can only occur on the surface, where it reacts to oxygen, as dust is far more flammable than other materials. All combustible dust needs to create a catastrophic event are the 4 additional elements on the featured pentagon graphic.

- There are Federal Standards. If you have combustible dust, you should be aware of the federal requirements to keep your facility safe and compliant. You’ll need to review the two standards on dust and fires in the wood industry issued by the National Fire Protection Association.

- NFPA 652, Standard on the Fundamentals of Combustible Dust. This standard details combustible dust in the workplace and describes several ways to safely eliminate the risks associated. You’ll also find the requirement of a Dust Hazard Analysis (DHA) in all facilities with combustible dust.

- NFPA 664, Standard for the Prevention of Fires and Explosions in Wood Processing and Woodworking Facilities. In this standard, you’ll find the exact amount of dust you are permitted before it becomes a fire hazard. (To quote the standard, “A deflagration hazard shall be determined to exist where the layer of accumulated fugitive wood dust on upward-facing surfaces exceeds 3.2mm (1/8”) over 5 percent of the area or 93m2 (1000 ft2), whichever is smaller.”

- SonicAire Dust Control Fans Eliminate all Concern of Wood Dust. Dust control fans are mentioned specifically in NFPA 652, and SonicAire fans come with a guarantee of compliance and safety. Once you’ve installed our fans, these wood dust worries become a thing of the past.

What You Need to Do About Wood Dust

- Conduct a Dust Hazard Analysis (DHA).A DHA is mandatory for all facilities with combustible dust, as we mentioned above. But what happens if you don’t have one? You may be fined by OSHA, or you may have your facility shut down until you fix the issue. Without knowing the specific areas of concern that a DHA details, you put your employees and your entire facility at risk. Simply put, it’s not worth the risk. (If you’re unsure what happens after a DHA, check out our conversation with DEKRA specialist Kevin Jeffries.)

- Resolve All Issues Found on the DHA. The DHA will explain every concern your facility has for combustible dust and propose solutions for each. You can opt for the solutions they suggest, or you may find alternatives that fit your facility better. (Check with the inspectors, though. It may not be a negotiable item for compliance.)

- Control Your Facility’s Wood Dust. This may be obvious, especially after all you’ve read here, but you’ll need to find a solution that works for your company. Clean it manually with dedicated employees, repropose your employees frequently to remove the dust, hire a cleaning crew, or prevent it from accumulating. Just remember, though: as with any mess, it’s far easier to prevent it from happening than to clean it up. SonicAire dust control fans will prevent accumulation, keeping your facility safe and compliant.

- Catch What Your Filtration System Misses. When your filtration system isn’t catching all the fugitive dust in your facility, you’ll need to take steps to prevent the build up in additional ways. Remember, a filtration system simply isn’t meant to catch it all. Check our video You Ask. We Answer. – How to Capture the Dust Your Filtration System Misses for more on that.

The Hazards of Wood Dust

The dust found in a woodworking facility gathers on every surface, and its build-up can be extremely hazardous. Within this industry, numerous processes can generate enough dust to pose a hazard. The more obvious methods of sawing, planning, routing, and sanding make the list, but other processes, such as sawdust delivery and pellet creation, also add to dust deposits.

Advances in wood production haven’t made dust control any easier. High-efficiency machines create finer dust particles, and their increased production capabilities result in more dust overall. And unfortunately, even the most modern dust collection methods have a hard time keeping up high levels of dust production.

The challenge for wood product facilities is how to handle the accumulation of this combustible dust.

What You Need to Know About Wood Dust

- Wood Dust is Combustible. You probably already know that, sure. But here’s why: Because wood dust is so fine, each particle of dust has a huge surface area compared to its mass. Burning can only occur on the surface, where it reacts to oxygen, as dust is far more flammable than other materials. All combustible dust needs to create a catastrophic event are the 4 additional elements on the featured pentagon graphic.

- There are Federal Standards. If you have combustible dust, you should be aware of the federal requirements to keep your facility safe and compliant. You’ll need to review the two standards on dust and fires in the wood industry issued by the National Fire Protection Association.

- NFPA 652, Standard on the Fundamentals of Combustible Dust. This standard details combustible dust in the workplace and describes several ways to safely eliminate the risks associated. You’ll also find the requirement of a Dust Hazard Analysis (DHA) in all facilities with combustible dust.

- NFPA 664, Standard for the Prevention of Fires and Explosions in Wood Processing and Woodworking Facilities. In this standard, you’ll find the exact amount of dust you are permitted before it becomes a fire hazard. (To quote the standard, “A deflagration hazard shall be determined to exist where the layer of accumulated fugitive wood dust on upward-facing surfaces exceeds 3.2mm (1/8”) over 5 percent of the area or 93m2 (1000 ft2), whichever is smaller.”)

- SonicAire Dust Control Fans Eliminate all Concern of Wood Dust. Dust control fans are mentioned specifically in NFPA 652, and SonicAire fans come with a guarantee of compliance and safety. Once you’ve installed our fans, these wood dust worries become a thing of the past.

What You Need to Do About Wood Dust

- Conduct a Dust Hazard Analysis (DHA). A DHA is mandatory for all facilities with combustible dust, as we mentioned above. But what happens if you don’t have one? You may be fined by OSHA, or you may have your facility shut down until you fix the issue. Without knowing the specific areas of concern that a DHA details, you put your employees and your entire facility at risk. Simply put, it’s not worth the risk. (If you’re unsure what happens after a DHA, check out our conversation with DEKRA specialist Kevin Jeffries.)

- Resolve All Issues Found on the DHA. The DHA will explain every concern your facility has for combustible dust and propose solutions for each. You can opt for the solutions they suggest, or you may find alternatives that fit your facility better. (Check with the inspectors, though. It may not be a negotiable item for compliance.)

- Control Your Facility’s Wood Dust. This may be obvious, especially after all you’ve read here, but you’ll need to find a solution that works for your company. Clean it manually with dedicated employees, repropose your employees frequently to remove the dust, hire a cleaning crew, or prevent it from accumulating. Just remember, though: as with any mess, it’s far easier to prevent it from happening than to clean it up. SonicAire dust control fans will prevent accumulation, keeping your facility safe and compliant.

- Catch What Your Filtration System Misses. When your filtration system isn’t catching all the fugitive dust in your facility, you’ll need to take steps to prevent the build up in additional ways. Remember, a filtration system simply isn’t meant to catch it all. Check our video You Ask. We Answer. – How to Capture the Dust Your Filtration System Misses for more on that.

How Do SonicAire Fans Keep OSB Facilities Compliant and Safe?

At Meadow Lake OSB, the dust produced by normal operations was simply too much to deal with. There was no possible way that staff could keep buildup below acceptable standards without shutting down operations and impacting productivity. At a production loss of $4,000 an hour each time they stopped to clean, it was obviously impacting profitability.

Click the video below for a case study of how SonicAire fans helped Meadow Lake OSB.

How Do SonicAire Fans Keep OSB Facilities Compliant and Safe?

At Meadow Lake OSB, the dust produced by normal operations was simply too much to deal with. There was no possible way that staff could keep buildup below acceptable standards without shutting down operations and impacting productivity. At a production loss of $4,000 an hour each time they stopped to clean, it was obviously impacting profitability.

Click the video below for a case study of how SonicAire fans helped Meadow Lake OSB.

High-Velocity Airflow

SonicAire’s specialized fans use high-velocity airflow to clean overhead areas. This ultra-powerful airflow effectively prevents the accumulation of combustible dust on overhead structures and provides

Thermal-Current Control

Typical airflow involves warm air currents naturally rising and lifting dust to overhead structures, where it accumulates quickly. SonicAire’s industrial dust control fans prevent these naturally occurring upward thermal currents from holding dust in the air in the first place. Our fans create an air barrier below the overhead structures, so the dust doesn’t rise above them and settle on top.

Using these two unique and efficient approaches, and with the help of our specialists, you can be assured that dust accumulation in your facility will be kept at a safe, minimal level.

Contact us today to speak to one of our trained specialists about how SonicAire can mitigate the danger of this dust in your facility. We would love to show you exactly how to make your workspace as safe as possible from dangerous buildup and save you time and money from having to do manual clean-up.

Here’s What Our Customers Have to Say About SonicAire

“It’s unbelievable the amount of labor savings and other things that go along with it. It’s impressive.”

“Sonicare fans have saved us a tremendous amount of time and labor.”

“…it helps employees and their frame of mind, to say they’re working in a nice, clean environment in a woodworking facility.”

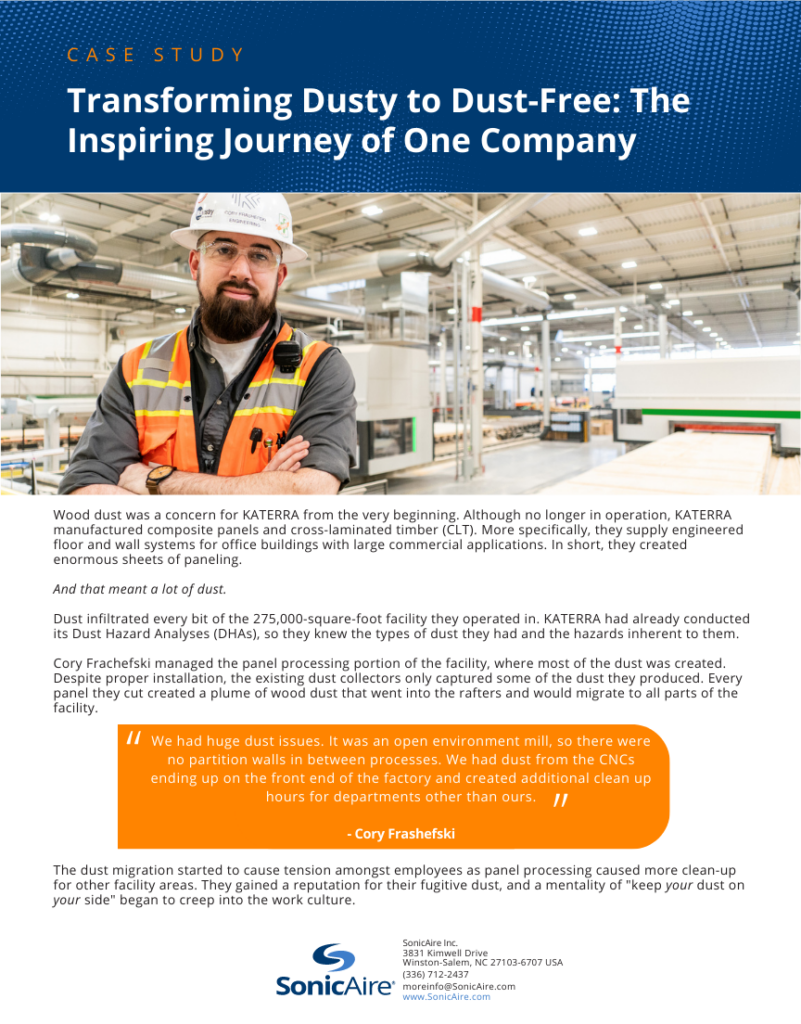

“We had huge dust issues. It was an open environment mill, so there were no partition walls in between processes. We had dust from the CNCs ending up on the front end of the factory and created additional clean up hours for departments other than ours.”

What Does Wood Dust Have to Do With Your Insurance?

When it comes to insurance, you want to be covered for all possible hazards at the best rate available. When an insurer evaluates your facility to prepare an offer of coverage, they look closely at your housekeeping. Dust accumulation may prevent you from receiving the best offer – or any offer at all.

SonicAire can help your facility appear particularly attractive to potential insurance companies, making it easier to get the best value from the best insurance. Take our relationship with Pennsylvania Lumberman’s Mutual Insurance company; they actually provide their clients discount to purchase SonicAire fans. Other insurance companies will offer reduction in the cost when the facility has our dust control fans installed.

Check out how in the video below.

Wood Industry Overview

This leading market employs nearly 900,000 people at more than 14,400 facilities across the United States. Nationwide, revenue from the wood products industry totaled nearly $130 billion in 2018-2019. Woodworking companies rank in the top 10 manufacturing employers in 47 states.

What products contribute to these numbers? Major market segments of the wood industry include:

- Sawmills and Lumber Production

- Engineered Wood Manufacturing

- Prefabricated Home Manufacturing

- RV Manufacturing

- Furniture Manufacturing

- Millwork Manufacturing

- Wood Pulp

- Wood Bioenergy / Wood Pellets

- Wood Pallet Manufacturing

You’ve Completed Your DHA. Now What?

With years of experience in testing and consulting on combustible dust hazards and nearly a century of operations focusing on safety, DEKRA is an excellent all-around resource for your specialized demands.

Click below to watch this conversation and discover the best next steps once you’ve completed your DHA.

Additional Resources

Learn more about how we helped companies like yours find solutions to their dust problems.

Complimentary Dust Management Plan with ROI Analysis

Our analysis will also show you the expected Return on Investment, including equipment investment, estimated annual savings and cumulative cashflow benefit.

Get started by contacting us today for your custom facility review, ROI analysis and fan technology proposal.

Get Your Complimentary Dust Management Plan with ROI Analysis

Our analysis will also show you the expected Return on Investment, including equipment investment, estimated annual savings and cumulative cashflow benefit.

Get started by contacting us today for your custom facility review, ROI analysis and fan technology proposal.