Automating Dust Control: Horry County Solid Waste Authority’s Journey to Becoming a Safer Facility

In Conway, SC, at the Horry County Solid Waste Authority Recycling Facility, over 100 tons of recyclable waste is processed each day. The Material Recycling Facility (MRF) processes all the recyclables in Horry county to reduce the overall tonnage the county contributes to landfills.

Deputy Director of Recycling Rodney Cannon oversees the facility and aims to find ways to create a more efficient environment. He constantly strives to find new ways to automate their processes to operate cleaner, faster, and handle more recyclables. Especially since the Great Recession, the MRF has opted not only for safe efficiencies that reduce the amount of help required, saving them money, but also allowing them to keep up with their workload with fewer employees.

“In our warehouse facility where we do all the processing, we had problems with the dust getting everywhere.” – Rodney Cannon

However, the combustible dust built up in his facilities proved to be a constant hassle and a consistent struggle. During processing, recyclables produce several types of fibers, and those fibers make a significant amount of combustible dust. As it migrates to the ceilings, the dust build-up becomes far too much to manage within the scope of their everyday business. It required overtime that was unsustainable and put a strain on employees.

Regardless of the strain, however, the dust needed to be removed.

“For safety reasons, we had to get it clean. So, we were taking man lifts, putting people in with harnesses and sweeping.” – Rodney Cannon

By manually cleaning the dust build-up, Horry County MRF was spending literal weeks removing it from the ceilings. Each time employees we raised in the lift to sweep, they could only clean about 50 feet at a time. After cleaning all they could reach, they had to be lowered, repositioned, and start the sweeping process all over again. Overtime that leaves employees exhausted is demoralizing, even when it’s temporary. Unfortunately, it was never a one-and-done process.

Completing dust removal manually several times a year cost the company time and money.

Removal isn’t just about safety, either. If OSHA were to enter a facility on a surprise inspection, combustible dust build-up could result in steep fines and possibly even shutdowns. The pressure to avoid setbacks and shutdowns is tangible in a facility that aims to improve lives and protect the environment.

The SonicAire Case for Automating Dust Management

After discovering SonicAire dust control fans, Horry County MRF initially invested in six fans for their facility. But they didn’t stop there.

“We were very pleased with the first six [fans] that we purchased from SonicAire, and we actually bought six more.” – Rodney Cannon

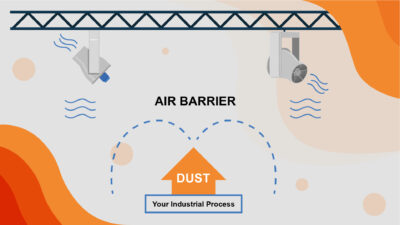

To minimize the dust build-up, they placed dust control fans strategically throughout their facility, as determined by SonicAire’s specialized engineers. Now, when dust and fibers are released during processing, SonicAire fans create a barrier preventing dust from ever entering the ceiling area. Our BarrierAire technology forces dust to the ground, making clean-up an easy sweep-and-done operation that can be completed as a short daily task.

Even better, this meant that MRF could reduce the hours spent on overtime after installing the SonicAire fans.

“Now, I’ve got something that can clean up without any manpower.” – Rodney Cannon

Visible Results

This automation has inevitably improved employee morale and the facility’s visible cleanliness. Cannon is confident that anyone who comes into his facility, especially others in the recycling industry, will be able to see the difference.

The Bottom Line

“From a health standpoint, it’s a lot safer without the dust.”- Rodney Cannon

Guaranteed Compliance

As long as SonicAire fans are correctly installed and maintained according to our engineers’ layout/engineering recommendations, they will eliminate the need for housekeeping in hard-to-reach overhead spaces.

And if they don’t, we’ll provide a full refund on the cost of fans or reimburse the cost of any imposed fine, whichever is less.*

*See SonicAire.com/Compliance-Guarantee for full details and terms.

Click the image to download the full case study from SonicAire.

Click the video below to hear more from Rodney Cannon about how SonicAire helped make his recycling facility a safer environment.

SonicAire is committed to helping our clients tackle combustible dust in their facilities.

Our team of experts will consult with you to develop a customized, engineered layout of SonicAire fans that helps reduce the risk of combustible dust events and keep facilities compliant with OSHA and NFPA regulations.

Get started by contacting us today for more information, or request your own engineered solution and quote.