Fear not, you can take the mystery out of your risks by learning more about the following five hidden ones you might not be thinking of yet. (And yes, we’re including combustible dust.)

Addressing the challenges facility managers and business owners face when maintaining safety and regulatory compliance is paramount for manufacturing companies. But do you really know all those risks when they’re not glaringly obvious?

The Importance of Addressing Unseen Risks

Hidden risks often go unnoticed but can have severe consequences for your employees and operations. This guide will highlight five unseen risks: poor air quality, noise pollution, accidents and general safety struggles, electrical hazards, and combustible dust. We will explore each risk in detail, providing actionable solutions to help you mitigate these dangers effectively.

1- Poor Air Quality and Its Effects on Production

The air quality within your facility plays a significant role in employee health and productivity. Breathing in air that is polluted with particulate or fumes can lead to respiratory problems, allergies, and other health issues that impact overall well-being. Moreover, stagnant air filled with contaminants can affect production efficiency and quality. To address these concerns, SonicAire offers an innovative solution that doesn’t require changing filters or any type of media.

Ensuring Clean Air with SonicAire Combustible Dust Control Fans

SonicAire’s state-of-the-art dust control fan systems are designed to cause the particulate in the air to agglomerate. Agglomeration is just a way of saying that by agitating the air, we get your dust to stick together and get too heavy to float on the air currents and fall to the floor. By strategically placing SonicAire’s one or two-horsepower, high-velocity airflow units in your facility, you can get rid of those halos around your facility lights and enjoy cleaner, clearer air.

Why Dust Assessment Matters

Before implementing any solution, you’ll want to assess your facility’s specific dust control needs. We highly recommend starting with a Dust Hazards Analysis. Additionally, SonicAire’s team of engineers can ensure that the fans’ airflow doesn’t negatively impact your production. All of our fans have adjustable oscillation controls to ensure that your people and processes are not affected by the fan system. Considering your space’s unique characteristics and challenges, SonicAire tailors its solutions to provide maximum effectiveness.

Protecting Employee Health and Productivity

Clean and fresh air is vital not only for the well-being of your employees but also for maintaining optimal productivity. SonicAire’s combustible dust control fan systems can significantly reduce airborne contaminants, creating a healthier workplace environment. This results in fewer sick days, increased employee satisfaction, and improved overall productivity. By investing in cleaner air, you invest in the well-being and success of your workforce.

2 – Noise Pollution and the Need for Ear Protection

Noise pollution is another hidden risk that often goes unnoticed until it becomes a significant problem. Excessive noise levels within a facility can lead to various health issues, including hearing loss, stress, and reduced focus. SonicAire offers relatively quiet and inobtrusive combustible dust control fan systems to mitigate this risk and contribute to a better work environment.

SonicAire Fans: Quiet and Efficient

You may wonder what a fan system is comparable to in terms of noise level. Most of our fan systems are mounted in the ceiling, so at about twenty feet away, they measure out at approximately 79 decibels, or the sound of your household washing machine or vacuum cleaner. Our customers have told us that they are a white noise that tends to blend into the other machinery sounds in their facility.

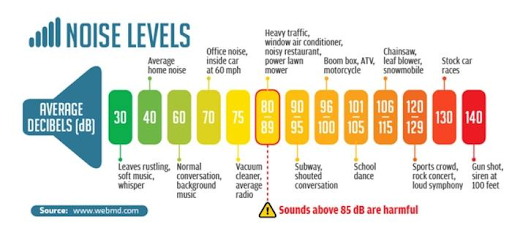

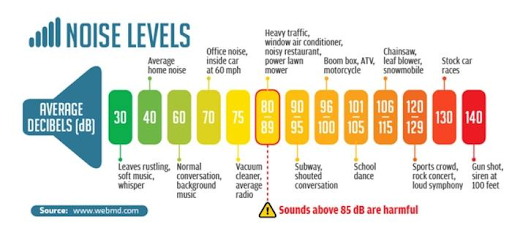

Understanding Decibel Levels and Everyday Comparisons

To put the quietness of SonicAire’s dust control fan systems into perspective, let’s take a look at decibel levels and some everyday comparisons:

- Whisper: 30 dB

- Library: 40 dB

- Office: 50 dB

- Hairdryer: 70 dB

- Washing machine: 80 dB

- Traditional industrial fan system: Up to 100 dB

As you can see, SonicAire’s fan systems are within the safe range of noise, ensuring minimal disruption and creating a comfortable working atmosphere.

3 – Accidents and General Safety Struggles

Accidents in the workplace can have severe consequences for your employees’ well-being and your company’s reputation. Chances for a slip and fall, respiratory controls, and other safety struggles pose significant risks that must be addressed promptly. At every possible point, you should be striving to minimize those dangers and create a safer environment for everyone.

Eliminating Slip and Fall Opportunities

The Occupational Safety and Health Administration (OSHA) lists fall protection as its most violated (and cited) safety concern. This can include going to the upper levels of a facility, whether by ladder, man lift, or other means. Having to clean overhead spaces as frequently as every day can put your employees at risk every time they do this. Unknown issues with equipment and slippery surfaces can cause serious issues to your personnel. By using an automated, maintenance-free solution like a fugitive dust control fan system, you can significantly reduce the likelihood of something like this happening.

Keeping Your Lungs Happy and Healthy

OSHA’s fourth most common citation and safety issue is respiratory protection.

In the control of those occupational diseases caused by breathing air contaminated with harmful dusts, fogs, fumes, mists, gases, smokes, sprays, or vapors, the primary objective shall be to prevent atmospheric contamination. This shall be accomplished as far as feasible by accepted engineering control measures (for example, enclosure or confinement of the operation, general and local ventilation, and substitution of less toxic materials). When effective engineering controls are not feasible, or while they are being instituted, appropriate respirators shall be used pursuant to this section.

Although you may not be able to see what’s in the air, you may feel it on your clothes or just smell it. The biggest danger when it comes to air quality is complacency, so whatever you choose, make sure you frequently check your control measures and keep them up-to-date.

4 – Electrical Hazards and Peace of Mind

Ensuring proper wiring within your facility is paramount for electrical safety. Faulty or outdated wiring increases the risk of electrical hazards, potentially resulting in devastating consequences. SonicAire addresses this concern by prioritizing expert installation and taking the necessary precautions to protect against electrical risks.

The Importance of Proper Wiring in Facilities

Outdated or poorly fitted wiring poses a considerable danger in manufacturing facilities. Over time, wear and tear on electrical components can lead to short circuits, overheating, and potential fires. SonicAire understands the importance of proper wiring and takes proactive measures to eliminate these risks.

SonicAire Fans: Expertly Installed for Safety

When you choose SonicAire Combustible Dust Control Fan Systems turn-key installation, you can rest assured that electrical safety is a top priority. Their team of trained professionals expertly installs each fan system, ensuring that all electrical components are securely connected and functioning optimally. By entrusting your facility’s electrical work to SonicAire, you mitigate the risk of accidents related to faulty wiring, providing peace of mind for employees and management.

5 – Combustible Dust: The (Somewhat) Invisible Threat

Now, we come to what some would call the unseen risk in manufacturing facilities: combustible dust. This seemingly harmless substance poses a severe threat when ignited, potentially leading to fires, explosions, and catastrophic damage. Understanding the nature of combustion, the importance of standards and regulations, and implementing appropriate solutions is crucial to ensuring the safety and well-being of everyone within your facility.

Understanding Combustion and Deflagration

Combustible dust refers to fine particles or fibers susceptible to ignition under specific conditions. When dispersed in the air, these particles can form explosive mixtures that, when ignited, result in rapid combustion, known as deflagration. Combustion occurs when fuel, oxygen, and an ignition source combine, creating heat and releasing gases. Therefore, dust, the air in your facility, and any spark or flame could create that perfect storm of a tragic situation. Without proper control measures, this process can quickly escalate into devastating explosions.

The Importance of Standards and Regulations

Recognizing the dangers posed by combustible dust, regulatory bodies have established strict guidelines and standards to protect workers and minimize the risk of explosions. Compliance with these regulations not only ensures the safety of your employees but also safeguards your facility against legal consequences and financial loss resulting from accidents. SonicAire understands the importance of adherence to these standards and works closely with customers to ensure full compliance.

SonicAire Combustible Dust Control Fans: Your Best Solution

When it comes to combatting combustible dust, SonicAire is your trusted partner. Our combustible dust control fan systems are designed to prevent the accumulation and dispersion of dust particles, minimizing the risk of explosions. By creating high-velocity laminar airflow, SonicAire’s fan systems disrupt settling dust, keeping it from accumulating on surfaces where ignition sources may be present. This innovative solution eliminates the conditions necessary for combustion, providing a safe and compliant environment.

A Safer Facility Starts Today

Addressing unseen risks in your facility is vital for maintaining safety, protecting employee well-being, and ensuring regulatory compliance. Poor air quality, noise pollution, accidents and general safety struggles, electrical hazards, and combustible dust pose significant dangers requiring immediate attention. SonicAire’s innovative combustible dust control fan systems can tackle these risks head-on, improving your facility’s safety and efficiency.

How Can You Improve Safety in Your Facility?

Reflect on the hidden risks we discussed throughout this article and consider how you can improve safety in your facility. Assess each risk area and take proactive measures to address them accordingly. Remember, a safer workplace leads to happier employees, increased productivity, and reduced liability.

Ready to Tackle the Unseen Risks? Request a Quote Today!

If you’re ready to create a safer and more compliant facility, contact SonicAire today. Request a quote on a guaranteed solution and take the first step towards mitigating unseen risks, protecting your employees, and ensuring regulatory compliance. Your facility’s safety is our top priority.

The Real Cost of Manual Dust Cleaning

It isn’t until you sit down and start adding up all of the costs the problem becomes apparent.

SonicAire Fans – A Cost-Effective Alternative

We’re not going to lie to you. Installing a SonicAire Dust Control Fan System requires an investment. There are very few facilities that can get by with a couple of fans. But the long-term benefits speak for themselves.

SonicAire fans either run for specified periods during the day or all day, depending upon your operations and dust production level. However, they use two different tactics to prevent combustible dust buildup in overhead areas.

First, they clean off higher surfaces with continual airflow. This prevents buildup and eliminates the cleaning of these areas. Second, a properly engineered system creates an Air Barrier to prevent warm air currents from bringing dust up into overhead spaces.

Let’s look at how they impact the costs we’ve highlighted above.

Measuring the Difference

Each facility is different. In manufacturing and processing, operations produce varying levels and types of fugitive dust. But each facility is likely overspending on manual cleaning or simply not cleaning enough.

When you consider the labor, equipment, and lost productivity that goes into manual cleaning practices and then add in the insurance costs, potential fines, and employee dissatisfaction. Is manually cleaning your facility really saving you money?

We’re confident our combustible dust control systems will save your facility money even with the initial investment to purchase and install. But, if you’re not 100% sold, we get it. That’s why we offer free dust management plans with ROI Analysis. These engineered plans recommend the amount and placing of fans to ensure maximum protection from dust buildup.

Click here to request your Free Dust Management Plan.

Or contact us to discuss dust control solutions for your facility.

Fear not, you can take the mystery out of your risks by learning more about the following five hidden ones you might not be thinking of yet. (And yes, we’re including combustible dust.)

Addressing the challenges facility managers and business owners face when maintaining safety and regulatory compliance is paramount for manufacturing companies. But do you really know all those risks when they’re not glaringly obvious?

The Importance of Addressing Unseen Risks

Hidden risks often go unnoticed but can have severe consequences for your employees and operations. This guide will highlight five unseen risks: poor air quality, noise pollution, accidents and general safety struggles, electrical hazards, and combustible dust. We will explore each risk in detail, providing actionable solutions to help you mitigate these dangers effectively.

1- Poor Air Quality and Its Effects on Production

The air quality within your facility plays a significant role in employee health and productivity. Breathing in air that is polluted with particulate or fumes can lead to respiratory problems, allergies, and other health issues that impact overall well-being. Moreover, stagnant air that is filled with contaminants can affect production efficiency and quality. To address these concerns, SonicAire offers an innovative solution that doesn’t require changing filters or any type of media.

Ensuring Clean Air with SonicAire Combustible Dust Control Fans

SonicAire’s state-of-the-art dust control fan systems are designed to cause the particulate in the air to agglomerate. Agglomeration is just a way of saying that by agitating the air, we get your dust to stick together and get too heavy to float on the air currents and fall to the floor. By strategically placing SonicAire’s one or two-horsepower, high-velocity airflow units in your facility, you can get rid of those halos around your facility lights and enjoy cleaner, clearer air.

Why Dust Assessment Matters

Before implementing any solution, you’ll want to assess your facility’s specific dust control needs. We highly recommend starting with a Dust Hazards Analysis. Additionally, SonicAire’s team of engineers can ensure that the fans’ airflow doesn’t negatively impact your production. All of our fans have adjustable oscillation controls to ensure that your people and processes are not affected by the fan system. Considering your space’s unique characteristics and challenges, SonicAire tailors its solutions to provide maximum effectiveness.

Protecting Employee Health and Productivity

Clean and fresh air is vital not only for the well-being of your employees but also for maintaining optimal productivity. SonicAire’s combustible dust control fan systems can significantly reduce airborne contaminants, creating a healthier workplace environment. This results in fewer sick days, increased employee satisfaction, and improved overall productivity. By investing in cleaner air, you invest in the well-being and success of your workforce.

2 – Noise Pollution and the Need for Ear Protection

Noise pollution is another hidden risk that often goes unnoticed until it becomes a significant problem. Excessive noise levels within a facility can lead to various health issues, including hearing loss, stress, and reduced focus. SonicAire offers relatively quiet and inobtrusive combustible dust control fan systems to mitigate this risk and contribute to a better work environment.

SonicAire Fans: Quiet and Efficient

You may wonder what a fan system is comparable to in terms of noise level. Most of our fan systems are mounted in the ceiling, so at about twenty feet away, they measure out at approximately 79 decibels, or the sound of your household washing machine or vacuum cleaner. Our customers have told us that they are a white noise that tends to blend into the other machinery sounds in their facility.

Understanding Decibel Levels and Everyday Comparisons

To put the sound of SonicAire’s dust control fan systems into perspective, let’s take a look at decibel levels and some everyday comparisons:

- Whisper: 30 dB

- Library: 40 dB

- Office: 50 dB

- Hairdryer: 70 dB

- Washing machine: 80 dB

- Traditional industrial fan system: Up to 100 dB

As you can see, SonicAire’s fan systems are within the safe range of noise, ensuring minimal disruption and creating a comfortable working atmosphere.

3 – Common Accidents and Safety Struggles

Accidents in the workplace can have severe consequences for your employees’ well-being and your company’s reputation. Chances for a slip and fall, respiratory controls, and other safety struggles pose significant risks that must be addressed promptly. At every possible point, you should be striving to minimize those dangers and create a safer environment for everyone.

Eliminating Slip and Fall Opportunities

The Occupational Safety and Health Administration (OSHA) lists fall protection as its most violated (and cited) safety concern. This can include going to the upper levels of a facility, whether by ladder, man lift, or other means. Having to clean overhead spaces as frequently as every day can put your employees at risk every time they do this. Unknown issues with equipment and slippery surfaces can cause serious issues to your personnel. By using an automated, maintenance-free solution like a fugitive dust control fan system, you can significantly reduce the likelihood of something like this happening.

Keeping Your Lungs Happy and Healthy

OSHA’s fourth most common citation and safety issue is respiratory protection.

In the control of those occupational diseases caused by breathing air contaminated with harmful dusts, fogs, fumes, mists, gases, smokes, sprays, or vapors, the primary objective shall be to prevent atmospheric contamination. This shall be accomplished as far as feasible by accepted engineering control measures (for example, enclosure or confinement of the operation, general and local ventilation, and substitution of less toxic materials). When effective engineering controls are not feasible, or while they are being instituted, appropriate respirators shall be used pursuant to this section.

Although you may not be able to see what’s in the air, you may feel it on your clothes or just smell it. The biggest danger when it comes to air quality is complacency, so whatever you choose, make sure you frequently check your control measures and keep them up-to-date.

4 – Electrical Hazards and Peace of Mind

Ensuring proper wiring within your facility is paramount for electrical safety. Faulty or outdated wiring increases the risk of electrical hazards, potentially resulting in devastating consequences. SonicAire addresses this concern by prioritizing expert installation and taking the necessary precautions to protect against electrical risks.

The Importance of Proper Wiring in Facilities

Outdated or poorly fitted wiring poses a considerable danger in manufacturing facilities. Over time, wear and tear on electrical components can lead to short circuits, overheating, and potential fires. SonicAire understands the importance of proper wiring and takes proactive measures to eliminate these risks.

SonicAire Fans: Expertly Installed for Safety

When you choose SonicAire Combustible Dust Control Fan Systems turn-key installation, you can rest assured that electrical safety is a top priority. Their team of trained professionals expertly installs each fan system, ensuring that all electrical components are securely connected and functioning optimally. By entrusting your facility’s electrical work to SonicAire, you mitigate the risk of accidents related to faulty wiring, providing peace of mind for employees and management.

5 – Combustible Dust: The (Somewhat) Invisible Threat

Now, we come to what some would call the unseen risk in manufacturing facilities: combustible dust. This seemingly harmless substance poses a severe threat when ignited, potentially leading to fires, explosions, and catastrophic damage. Understanding the nature of combustion, the importance of standards and regulations, and implementing appropriate solutions is crucial to ensuring the safety and well-being of everyone within your facility.

Understanding Combustion and Deflagration

Combustible dust refers to fine particles or fibers susceptible to ignition under specific conditions. When dispersed in the air, these particles can form explosive mixtures that, when ignited, result in rapid combustion, known as deflagration. Combustion occurs when fuel, oxygen, and an ignition source combine, creating heat and releasing gases. Therefore, dust, the air in your facility, and any spark or flame could create that perfect storm of a tragic situation. Without proper control measures, this process can quickly escalate into devastating explosions.

The Importance of Standards and Regulations

Recognizing the dangers posed by combustible dust, regulatory bodies have established strict guidelines and standards to protect workers and minimize the risk of explosions. Compliance with these regulations not only ensures the safety of your employees but also safeguards your facility against legal consequences and financial loss resulting from accidents. SonicAire understands the importance of adherence to these standards and works closely with customers to ensure full compliance.

SonicAire Combustible Dust Control Fans: Your Best Solution

When it comes to combatting combustible dust, SonicAire is your trusted partner. Our combustible dust control fan systems are designed to prevent the accumulation and dispersion of dust particles, minimizing the risk of explosions. By creating high-velocity laminar airflow, SonicAire’s fan systems disrupt settling dust, keeping it from accumulating on surfaces where ignition sources may be present. This innovative solution eliminates the conditions necessary for combustion, providing a safe and compliant environment.

A Safer Facility Starts Today

Addressing unseen risks in your facility is vital for maintaining safety, protecting employee well-being, and ensuring regulatory compliance. Poor air quality, noise pollution, accidents and general safety struggles, electrical hazards, and combustible dust pose significant dangers requiring immediate attention. SonicAire’s innovative combustible dust control fan systems can tackle these risks head-on, improving your facility’s safety and efficiency.

How Can You Improve Safety in Your Facility?

Reflect on the hidden risks we discussed throughout this article and consider how you can improve safety in your facility. Assess each risk area and take proactive measures to address them accordingly. Remember, a safer workplace leads to happier employees, increased productivity, and reduced liability.

Ready to Tackle the Unseen Risks? Request a Quote Today!

If you’re ready to create a safer and more compliant facility, contact SonicAire today. Request a quote on a guaranteed solution and take the first step towards mitigating unseen risks, protecting your employees, and ensuring regulatory compliance. Your facility’s safety is our top priority.

The Real Cost of Manual Dust Cleaning

It isn’t until you sit down and start adding up all of the costs the problem becomes apparent.

SonicAire Fans – A Cost-Effective Alternative

We’re not going to lie to you. Installing a SonicAire Dust Control Fan System requires an investment. There are very few facilities that can get by with a couple of fans. But the long-term benefits speak for themselves.

SonicAire fans either run for specified periods during the day or all day, depending upon your operations and dust production level. However, they use two different tactics to prevent combustible dust buildup in overhead areas.

First, they clean off higher surfaces with continual airflow. This prevents buildup and eliminates the cleaning of these areas. Second, a properly engineered system creates an Air Barrier to prevent warm air currents from bringing dust up into overhead spaces.

Let’s look at how they impact the costs we’ve highlighted above.

Measuring the Difference

Each facility is different. In manufacturing and processing, operations produce varying levels and types of fugitive dust. But each facility is likely overspending on manual cleaning or simply not cleaning enough.

When you consider the labor, equipment, and lost productivity that goes into manual cleaning practices and then add in the insurance costs, potential fines, and employee dissatisfaction. Is manually cleaning your facility really saving you money?

We’re confident our combustible dust control systems will save your facility money even with the initial investment to purchase and install. But, if you’re not 100% sold, we get it. That’s why we offer free dust management plans with ROI Analysis. These engineered plans recommend the amount and placing of fans to ensure maximum protection from dust buildup.

Click here to request your Free Dust Management Plan.

Or contact us to discuss dust control solutions for your facility.

GET YOUR FREE GUIDE:

The Real Cost of Fugitive Dust in Hard-to-Reach Spaces

What You Can’t See Can Hurt You

To help protect your workplace, we’ve compiled the following resource, The Real Cost of Fugitive Dust in Hard-to-Reach Spaces: What You Can’t See Can Hurt You. In it, we identify seven ways fugitive dust is likely impacting your facility and its profitability.

These costs go beyond housekeeping and explain why you should be preventing dust buildup to protect the bottom line, not just to stay in compliance.