Controlling dust is crucial to maintaining a safe and compliant manufacturing facility. That’s where SonicAire comes in. With its innovative BarrierAire™ technology and customized fan layouts, SonicAire offers a game-changing solution that prevents combustible dust issues before they escalate, ensuring safety and regulatory compliance.

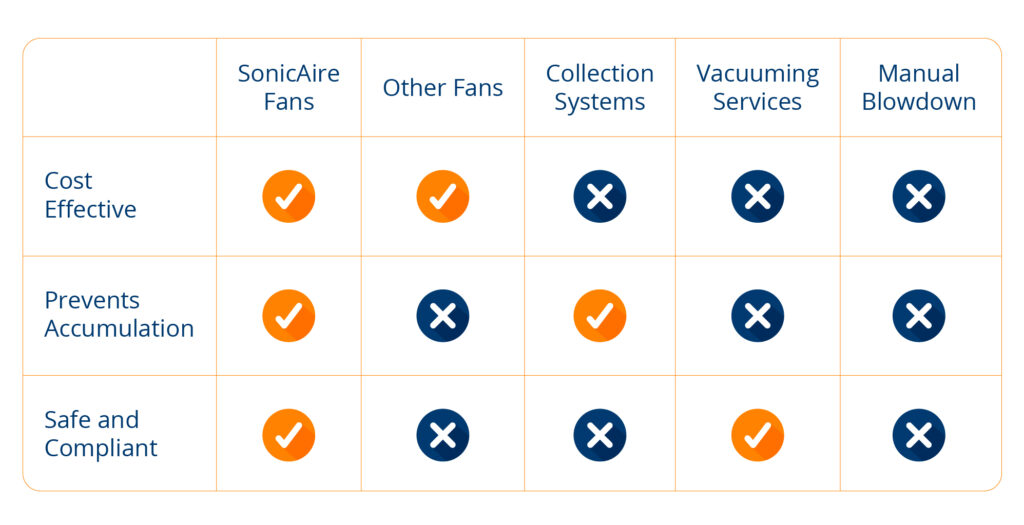

This guide will compare SonicAire’s dust control solutions with competing products such as dust collection systems, vacuuming services, and manual blow-down methods. We’ll explore the strengths and weaknesses of each approach, highlighting why SonicAire stands out from the crowd.

The Competitive Landscape in Dust Control

There are several options available for managing fugitive dust in manufacturing facilities. From traditional dust collection systems to vacuuming services and manual blow-down methods, businesses have tried various approaches to keeping their facilities clean and safe.

However, not all dust control solutions are created equal. Some methods may fail to effectively contain and prevent dust particle spread. Below, we get into the specifics of how SonicAire’s dust control solutions compare to these alternatives. Ultimately, options like vacuuming and blow-downs are reactive methods of dust control, while our SonicAire dust control fans use a proactive approach.

Here’s the key takeaway: SonicAire fans are the best way to ensure you’re always safe and compliant on combustible dust.

SonicAire Dust Control Fans

Unlike traditional fan systems or compressed air that simply blows dust particles around your facility, SonicAire’s BarrierAire™ technology keeps the dust at an easily accessible level. This innovative approach enhances safety and reduces maintenance costs associated with cleaning dust buildup on equipment, rafters, and other hard-to-reach areas.

SonicAire customizes fan placement layouts based on each facility’s unique needs. Their team of expert engineers considers factors such as the type of dust, production processes, and facility layout to create an optimized plan for maximum effectiveness. With SonicAire, you can rest assured that your dust control solution will be tailored to your facility’s requirements and dust type throughout your processes.

Competing Fans

While other fan systems on the market imply they’re effective in dust control, they are not built with the same innovation, attention to detail, and durability as SonicAire fans.

The dust control fan you’ll get from our competitors is the same fan you would’ve received if you ordered it 20 years ago. Not so with SonicAire. Our fans are continually optimized for sustainability, efficiency, longevity, and ease of use.

Our fans come in one-, two-, and three-horsepower options, while our competitors only offer one-horsepower fans. This difference is important to note when looking at an engineered layout of fan placement. Do not put a one-horsepower fan where a two-horsepower fan is needed. It will put your facility at risk of non-compliance or a potentially tragic event.

SonicAire’s advanced motor efficiency and size make its fan systems more energy-efficient than those of its competitors. Using cutting-edge technology, SonicAire outperforms the competition while minimizing energy consumption, resulting in long-term business savings.

To provide a comprehensive comparison, let’s take a closer look at some of the pros and cons of competing dust control fan solutions:

Pros of Other Fans:

- Cost-effective initial investment

Cons of Other Fans:

- Limited capability in directing airflow

- Higher maintenance requirements and shorter product lifespan

- Less efficient motor resulting in higher energy consumption

- Limited customization options for different facility layouts

- Smaller motor size, meaning you’ll need more fans for your facility

- No preventive maintenance program or certified installation options

By evaluating these factors, it becomes clear that SonicAire’s innovative approach and superior capabilities set them apart from the competition.

Bottom Line? Other fans just push the dust around and fail to bring you the innovation and quality of products and services that SonicAire offers.

Dust Collection Systems

Dust collection systems have long been popular for managing airborne dust in manufacturing facilities. These systems utilize a combination of ventilation and filtration mechanisms to capture and contain dust particles.

While effective in part, dust collection systems may face challenges over time. As production processes change, equipment is added or removed, or the facility layout is modified, these systems can become less efficient at capturing and containing dust. Inadequate maintenance can further exacerbate their performance degradation.

Let’s consider some of the pros and cons of using dust collection systems compared to SonicAire’s fan-based approach:

Pros of Dust Collection Systems:

- Effective at capturing dust particles during the initial implementation

- Centralized system for capturing dust from multiple sources

Cons of exclusive use of Dust Collection Systems:

- Decreased efficiency as facility layout or production processes change

- Requires regular maintenance to ensure optimal performance

- Potential for higher installation and operational costs compared to fan systems

It’s important to note that SonicAire fans are meant to work in tandem with your existing system to control the fugitive dust that inevitably escapes dust collectors.

In contrast, SonicAire’s fan-based solution is more adaptable to changing facility needs and requires less maintenance to maintain optimal performance. By keeping dust down, SonicAire minimizes re-entrainment risk and provides ongoing dust control without regular maintenance or system modifications.

If you already have a dust collection system, it will be even more efficient when used in conjunction with our specialized dust control fans.

Watch our video, How to Capture the Combustible Dust Your Filtration System Misses, for more on why your filtration system alone is insufficient for handling your fugitive dust.

Bottom Line? Dust collectors aren’t a stand-alone solution. They’re best used in conjunction with SonicAire fans.

Vacuuming Services

Another common approach to dust control in industrial facilities is vacuuming services. These services involve periodic surface cleaning to remove accumulated dust particles.

While vacuuming can effectively temporarily remove visible dust, it falls short when it comes to prevention. It is a reactive measure that does not address the root cause of the problem: airborne dust dispersion.

Consider these pros and cons when comparing vacuuming services to SonicAire’s continuous dust control solutions:

Pros of Vacuuming Services:

- Immediate removal of visible dust

- Suitable for spot cleaning

Cons of Vacuuming Services:

- Reactive approach rather than proactive

- Must shut down or limit production while vacuum team is cleaning

- Limited effectiveness in controlling airborne dust dispersion

- Regular service costs can add up over time

SonicAire’s fan-based approach, on the other hand, focuses on prevention rather than cleanup. By using high-velocity airflow to cause agglomeration of particulate, SonicAire fan systems ensure ongoing dust control without relying on periodic vacuuming services. This automated approach to dust control translates into significant cost savings and improved overall efficiency for manufacturing facilities.

Check out our case study here if you want more concrete statistical evidence. It explores how, before SonicAire dust control fans, one company spent $30,000 every year on manually cleaning combustible dust with vacuuming.

Bottom Line? Vacuuming services are the most expensive path you can take to compliance.

Manual Blowdown Methods

Some manufacturing facilities resort to manual blow-down methods to control dust. Typically, this involves using compressed air, leaf blowers, or manual sweeping to disperse dust particles.

However, manual blow-down methods come with inherent hazards. Blowing dust using compressed air can create a dangerous dust cloud that poses fire and explosion risks, violating safety guidelines such as NFPA 654 (soon to be NFPA 660). Additionally, manual sweeping may result in dust re-entrainment, leading to contamination and potential health hazards for workers.

Let’s explore the pros and cons of manual blow-down methods compared to SonicAire’s automated solution:

Pros of Manual Blowdown Methods:

- Immediate dispersion of visible dust in specific areas

Cons of Manual Blowdown Methods:

- Creates a dangerous dust cloud that can easily ignite

- Risk of worker exposure to contaminants during the process

- Overtime costs and shutdown of manufacturing/processing

- Limited effectiveness in controlling airborne dust dispersion

SonicAire’s fan-based solution offers an automated and safe alternative to manual blow-down methods. By effectively disturbing thermal currents that carry dust particulate to overhead spaces and getting that dust to agglomerate and fall to the floor, SonicAire ensures continuous control over airborne dust without jeopardizing safety or regulatory compliance.

Bottom Line? Manual blowdowns are dangerous and require shutting down operations, costing you time and money.

Finding the Best Dust Control Solution

There are several options to control fugitive dust in your facility. Each approach has pros and cons, from dust collection systems to vacuuming services and manual blow-down methods.

Which option has all the pros and none of the cons?

SonicAire sets itself apart with its unique BarrierAire™ technology and customized fan systems. What makes us unique is how we tackle dust right where it starts, keeping it under control so you’re never caught unprepared for an inspection or at risk for a combustible dust explosion. With SonicAire, you get a complete solution that boosts safety, cuts down on maintenance expenses, improves employee morale, and ensures regulatory compliance.

To learn more about how SonicAire’s dust control solutions can benefit your business, check out our additional resources or contact us to learn how we can keep you safe and compliant on combustible dust.

Controlling dust is crucial to maintaining a safe and compliant manufacturing facility. That’s where SonicAire comes in. With its innovative BarrierAire™ technology and customized fan layouts, SonicAire offers a game-changing solution that prevents combustible dust issues before they escalate, ensuring safety and regulatory compliance.

This guide will compare SonicAire’s dust control solutions with competing products such as dust collection systems, vacuuming services, and manual blow-down methods. We’ll explore the strengths and weaknesses of each approach, highlighting why SonicAire stands out from the crowd.

The Competitive Landscape in Dust Control

There are several options available for managing fugitive dust in manufacturing facilities. From traditional dust collection systems to vacuuming services and manual blow-down methods, businesses have tried various approaches to keeping their facilities clean and safe.

However, not all dust control solutions are created equal. Some methods may fail to effectively contain and prevent dust particle spread. Below, we get into the specifics of how SonicAire’s dust control solutions compare to these alternatives. Ultimately, options like vacuuming and blow-downs are reactive methods of dust control, while our SonicAire dust control fans use a proactive approach.

Here’s the key takeaway: SonicAire fans are the best way to ensure you’re always safe and compliant on combustible dust.

SonicAire Dust Control Fans

SonicAire’s dust control fan systems use our proven BarrierAire™ technology to tackle airborne dust that rides on thermal currents to overhead spaces. These specially engineered ceiling-mounted or mobile fan units harness the principles of agglomeration to cause dust particles to stick together. This process makes the air in your facility cleaner and clearer, leaving you with only dust on the floor to sweep up at the end of the day.

SonicAire customizes fan placement layouts based on each facility’s unique needs. Their team of expert engineers considers factors such as the type of dust, production processes, and facility layout to create an optimized plan for maximum effectiveness. With SonicAire, you can rest assured that your dust control solution will be tailored to your facility’s requirements and dust type throughout your processes.

Competing Fans

While other fan systems on the market imply they’re effective in dust control, they are not built with the same innovation, attention to detail, and durability as SonicAire fans.

The dust control fan you’ll get from our competitors is the same fan you would’ve received if you ordered it 20 years ago. Not so with SonicAire. Our fans are continually optimized for sustainability, efficiency, longevity, and ease of use.

Our fans come in one-, two-, and three-horsepower options, while our competitors only offer one-horsepower fans. This difference is important to note when looking at an engineered layout of fan placement. Do not put a one-horsepower fan where a two-horsepower fan is needed. It will put your facility at risk of non-compliance or a potentially tragic event.

SonicAire’s advanced motor efficiency and size make its fan systems more energy-efficient than those of its competitors. Using cutting-edge technology, SonicAire outperforms the competition while minimizing energy consumption, resulting in long-term business savings.

To provide a comprehensive comparison, let’s take a closer look at some of the pros and cons of competing dust control fan solutions:

Pros of Other Fans:

- Cost-effective initial investment

Cons of Other Fans:

- Limited capability in directing airflow

- Higher maintenance requirements and shorter product lifespan

- Less efficient motor resulting in higher energy consumption

- Limited customization options for different facility layouts

- Smaller motor size, meaning you’ll need more fans for your facility

- No preventive maintenance program or certified installation options

By evaluating these factors, it becomes clear that SonicAire’s innovative approach and superior capabilities set them apart from the competition.

Bottom Line? Other fans just push the dust around and fail to bring you the innovation and quality of products and services that SonicAire offers.

Dust Collection Systems

Dust collection systems have long been popular for managing airborne dust in manufacturing facilities. These systems utilize a combination of ventilation and filtration mechanisms to capture and contain dust particles.

While effective in part, dust collection systems may face challenges over time. As production processes change, equipment is added or removed, or the facility layout is modified, these systems can become less efficient at capturing and containing dust. Inadequate maintenance can further exacerbate their performance degradation.

Let’s consider some of the pros and cons of using dust collection systems compared to SonicAire’s fan-based approach:

Pros of Dust Collection Systems:

- Effective at capturing dust particles during the initial implementation

- Centralized system for capturing dust from multiple sources

Cons of exclusive use of Dust Collection Systems:

- Decreased efficiency as facility layout or production processes change

- Requires regular maintenance to ensure optimal performance

- Potential for higher installation and operational costs compared to fan systems

It’s important to note that SonicAire fans are meant to work in tandem with your existing system to control the fugitive dust that inevitably escapes dust collectors.

In contrast, SonicAire’s fan-based solution is more adaptable to changing facility needs and requires less maintenance to maintain optimal performance. By keeping dust down, SonicAire minimizes re-entrainment risk and provides ongoing dust control without regular maintenance or system modifications.

If you already have a dust collection system, it will be even more efficient when used in conjunction with our specialized dust control fans.

Watch our video, How to Capture the Combustible Dust Your Filtration System Misses, for more on why your filtration system alone is insufficient for handling your fugitive dust.

Bottom Line? Dust collectors aren’t a stand-alone solution. They’re best used in conjunction with SonicAire fans.

Vacuuming Services

Another common approach to dust control in industrial facilities is vacuuming services. These services involve periodic surface cleaning to remove accumulated dust particles.

While vacuuming can effectively temporarily remove visible dust, it falls short when it comes to prevention. It is a reactive measure that does not address the root cause of the problem: airborne dust dispersion.

Consider these pros and cons when comparing vacuuming services to SonicAire’s continuous dust control solutions:

Pros of Vacuuming Services:

- Immediate removal of visible dust

- Suitable for spot cleaning

Cons of Vacuuming Services:

- Reactive approach rather than proactive

- Must shut down or limit production while vacuum team is cleaning

- Limited effectiveness in controlling airborne dust dispersion

- Regular service costs can add up over time

SonicAire’s fan-based approach, on the other hand, focuses on prevention rather than cleanup. By using high-velocity airflow to cause agglomeration of particulate, SonicAire fan systems ensure ongoing dust control without relying on periodic vacuuming services. This automated approach to dust control translates into significant cost savings and improved overall efficiency for manufacturing facilities.

Check out our case study here if you want more concrete statistical evidence. It explores how, before SonicAire dust control fans, one company spent $30,000 every year on manually cleaning combustible dust with vacuuming.

Bottom Line? Vacuuming services are the most expensive path you can take to compliance.

Manual Blowdown Methods

Some manufacturing facilities resort to manual blow-down methods to control dust. Typically, this involves using compressed air, leaf blowers, or manual sweeping to disperse dust particles.

However, manual blow-down methods come with inherent hazards. Blowing dust using compressed air can create a dangerous dust cloud that poses fire and explosion risks, violating safety guidelines such as NFPA 654 (soon to be NFPA 660). Additionally, manual sweeping may result in dust re-entrainment, leading to contamination and potential health hazards for workers.

Let’s explore the pros and cons of manual blow-down methods compared to SonicAire’s automated solution:

Pros of Manual Blowdown Methods:

- Immediate dispersion of visible dust in specific areas

Cons of Manual Blowdown Methods:

- Creates a dangerous dust cloud that can easily ignite

- Risk of worker exposure to contaminants during the process

- Overtime costs and shutdown of manufacturing/processing

- Limited effectiveness in controlling airborne dust dispersion

SonicAire’s fan-based solution offers an automated and safe alternative to manual blow-down methods. By effectively disturbing thermal currents that carry dust particulate to overhead spaces and getting that dust to agglomerate and fall to the floor, SonicAire ensures continuous control over airborne dust without jeopardizing safety or regulatory compliance.

Bottom Line? Manual blowdowns are dangerous and require shutting down operations, costing you time and money.

Finding the Best Dust Control Solution

There are several options to control fugitive dust in your facility. Each approach has pros and cons, from dust collection systems to vacuuming services and manual blow-down methods.

But which has all the pros and none of the cons?

SonicAire sets itself apart with its unique BarrierAire™ technology and customized fan systems. What makes us unique is how we tackle dust right where it starts, keeping it under control so you’re never caught unprepared for an inspection or at risk for a combustible dust explosion. With SonicAire, you get a complete solution that boosts safety, cuts down on maintenance expenses, improves employee morale, and ensures regulatory compliance.

To learn more about how SonicAire’s dust control solutions can benefit your business, check out our additional resources or contact us to learn how we can keep you safe and compliant on combustible dust.

GET YOUR FREE GUIDE:

The Real Cost of Fugitive Dust in Hard-to-Reach Spaces

What You Can’t See Can Hurt You

To help protect your workplace, we’ve compiled the following resource, The Real Cost of Fugitive Dust in Hard-to-Reach Spaces: What You Can’t See Can Hurt You. In it, we identify seven ways fugitive dust is likely impacting your facility and its profitability.

These costs go beyond housekeeping and explain why you should be preventing dust buildup to protect the bottom line, not just to stay in compliance.