The constant presence of combustible dust in manufacturing facilities significantly threatens safety and regulatory compliance. In Class II Division 1 (CIID1) environments, the need for effective dust control solutions becomes even more critical because of this testy environment.

The constant presence of combustible dust in manufacturing facilities significantly threatens safety and regulatory compliance. In Class II Division 1 (CIID1) environments, the need for effective dust control solutions becomes even more critical because of this testy environment.

Combustible dust is highly volatile and can lead to devastating incidents if not adequately managed. Manual cleaning often falls short, resulting in inefficiency, downtime, and increased risks. Thankfully, SonicAire has revolutionized dust control with their game-changing BarrierAire™ technology and their latest innovation, the CIID1 Underwriters Laboratories-certified XZ-210 and XZ-215 fans.

The Importance of Compliance and Safety in CIID1 Environments

Maintaining compliance and ensuring safety are paramount in manufacturing facilities that deal with combustible dust. These Class II Division 1 (CIID1) environments pose unique challenges due to the constant presence of highly explosible dust particles in normal conditions. Oftentimes, the amount in suspension is enough to create an environment where the air is ignitable. Neglecting proper dust control measures can have severe consequences, ranging from equipment damage and production disruptions to life-threatening incidents. Proactive steps must be taken to prevent dust accumulation and promote regulatory compliance.

The Volatility of Combustible Dust: A Persistent Threat

Combustible dust, consisting of fine particles from various materials such as wood, metal, plastics, and chemicals, poses a significant risk in industrial environments. These highly volatile particles can combust when exposed to an ignition source, leading to catastrophic incidents. Throughout history, numerous disasters have occurred due to combustible dust explosions, causing loss of life, property damage, and environmental harm. The consequences of neglecting proper dust control measures have been devastating, from grain mills to woodworking facilities.

To prevent these incidents, manufacturing facility managers and business owners must proactively mitigate dust accumulation and ensure compliance with safety regulations.

The Challenges of Manual Cleaning in CIID1 Environments

Traditionally, manual cleaning has been the go-to method for addressing dust accumulation in industrial settings. However, this approach presents several challenges, especially in CIID1 environments. One of the primary obstacles is the halt in operations during the cleaning process. Shutting down production lines for cleaning leads to downtime and negatively impacts overall productivity and profitability. Additionally, manual cleaning often turns out to be inefficient and cost-prohibitive, requiring significant labor resources and recurring expenses for cleaning vendors, services, equipment, and supplies.

To add to the headache of manual cleaning in hazardous environments, don’t forget that there are inherent risks. Workers are exposed to potential dangers while attempting to remove accumulated dust manually, increasing the likelihood of accidents and injuries. A rogue spark or a new employee who doesn’t understand that a ShopVac becomes a bomb if you use it to vacuum up dust can destroy a facility and ruin lives in a heartbeat. Because of this, finding an alternative solution ensuring safety and efficiency becomes imperative.

SonicAire Fans: A Revolutionary Solution for Dust Control

Recognizing the limitations of traditional cleaning methods, SonicAire developed a revolutionary solution for effective dust control – BarrierAire™ technology. SonicAire’s dust control fans provide a game-changing approach by preventing dust accumulation before it ever becomes a hazard. With their strategic placement within manufacturing facilities, these fans disrupt the airflow patterns that allow dust particles to settle, eliminating manual cleaning and reducing the risks associated with combustible dust.

Facility managers and business owners across various industries have witnessed immediate benefits upon implementing SonicAire’s dust control fans. Increased productivity, improved safety, reduced maintenance costs, and enhanced regulatory compliance are just a few of the advantages of installing SonicAire dust control fans.

However, Class II Division 1 environments have always had a more difficult time safely maintaining compliance – as not all environments are created equally. Due to the constant presence of volatile dust in these areas, Underwriters Laboratories, or UL Solutions, is incredibly particular in giving any product a certification declaring it safe for use. Since beginning in 1894, they have never awarded a certification for a dust control fan in CIID1 environments.

That is, until now.

The Game-Changer: Introducing the CIID1-Certified XZ-210 and XZ-215 Fans

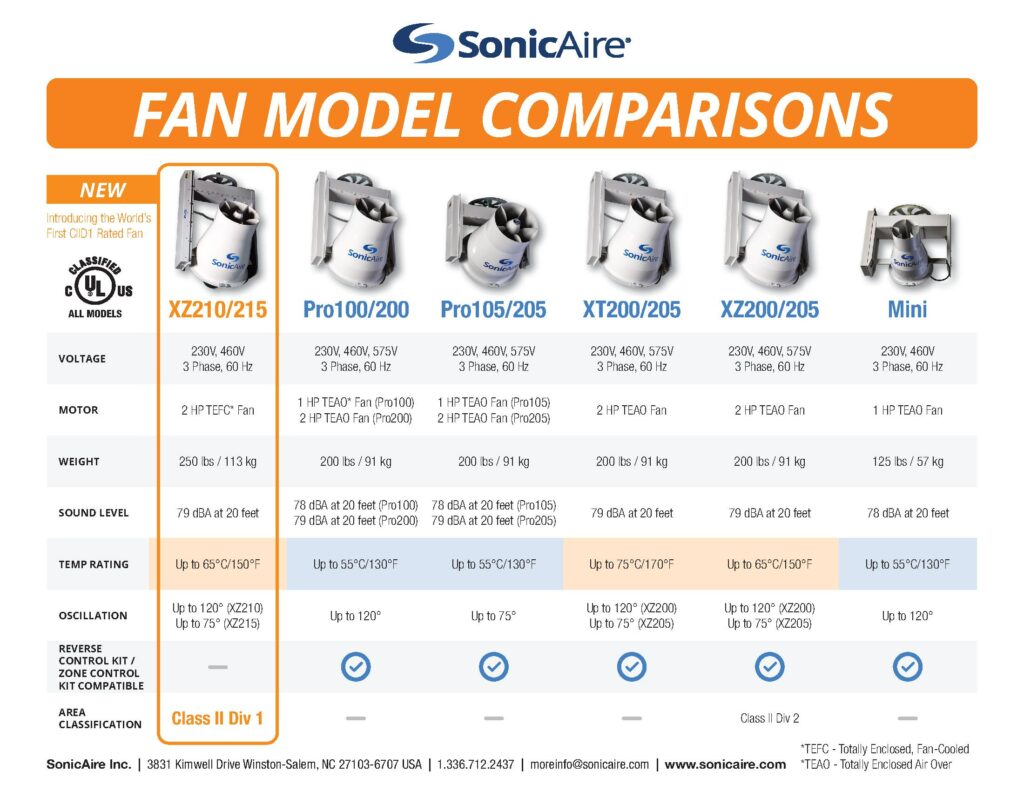

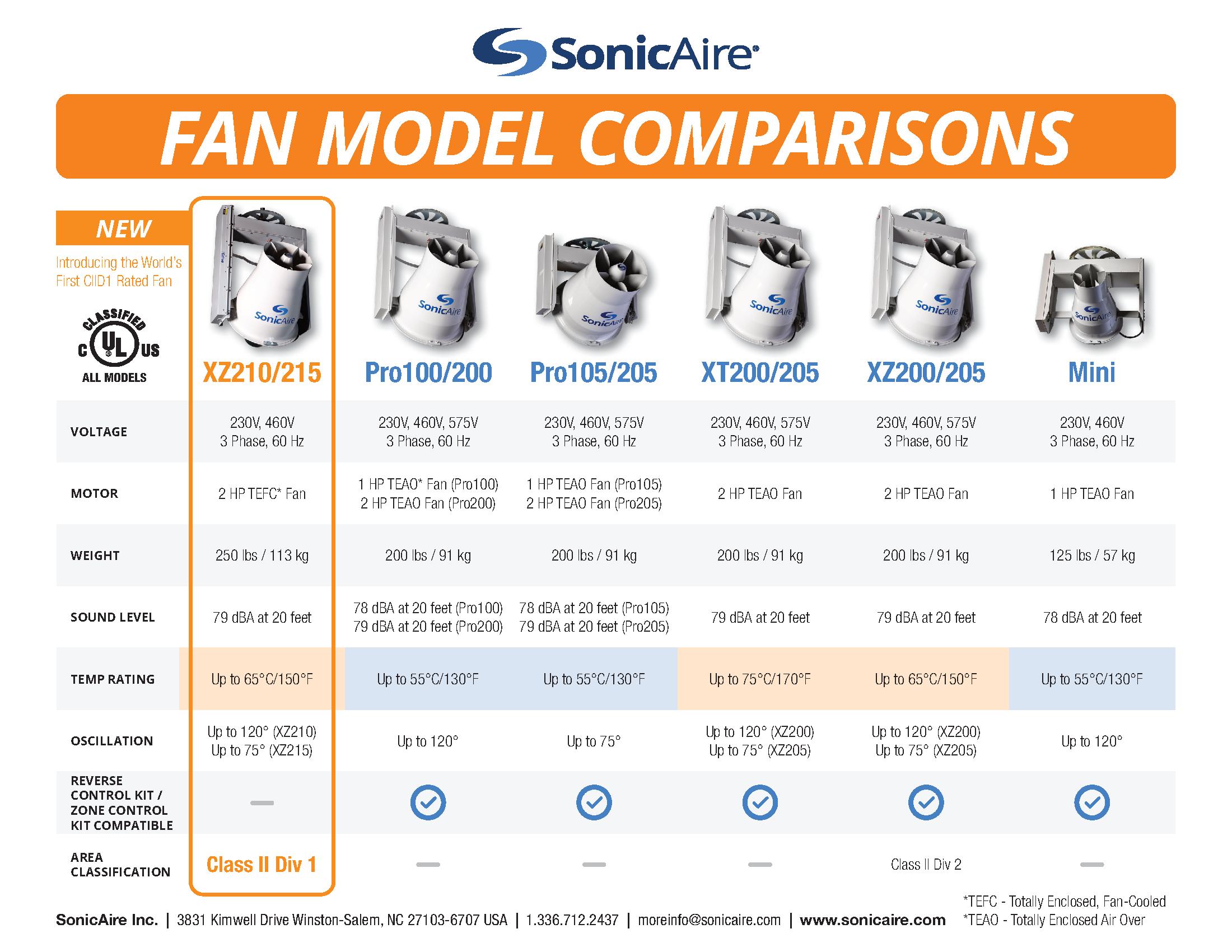

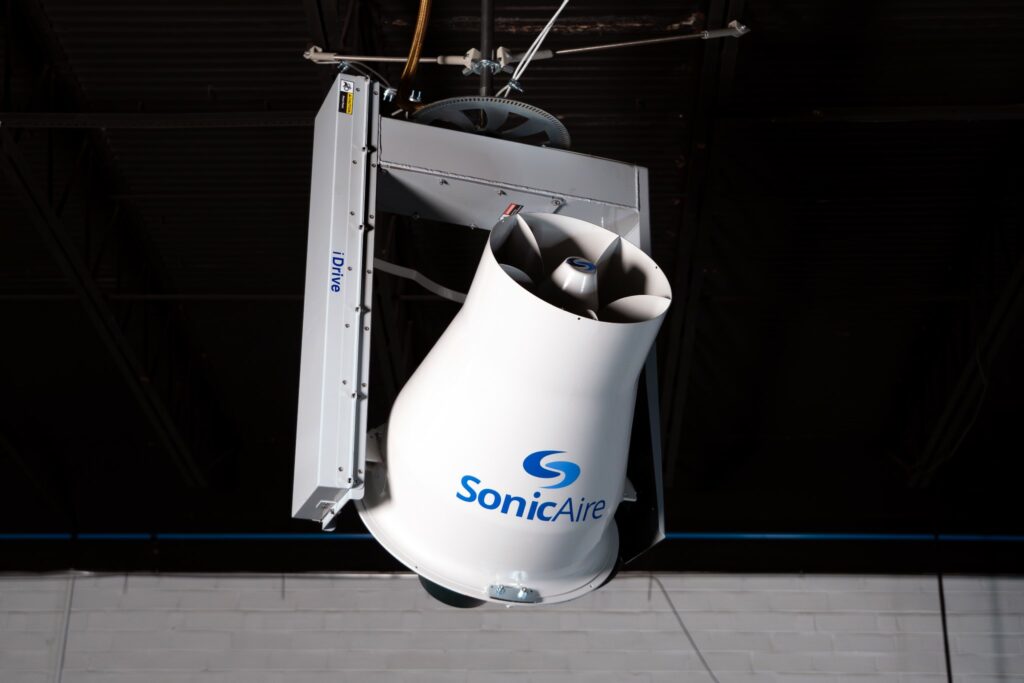

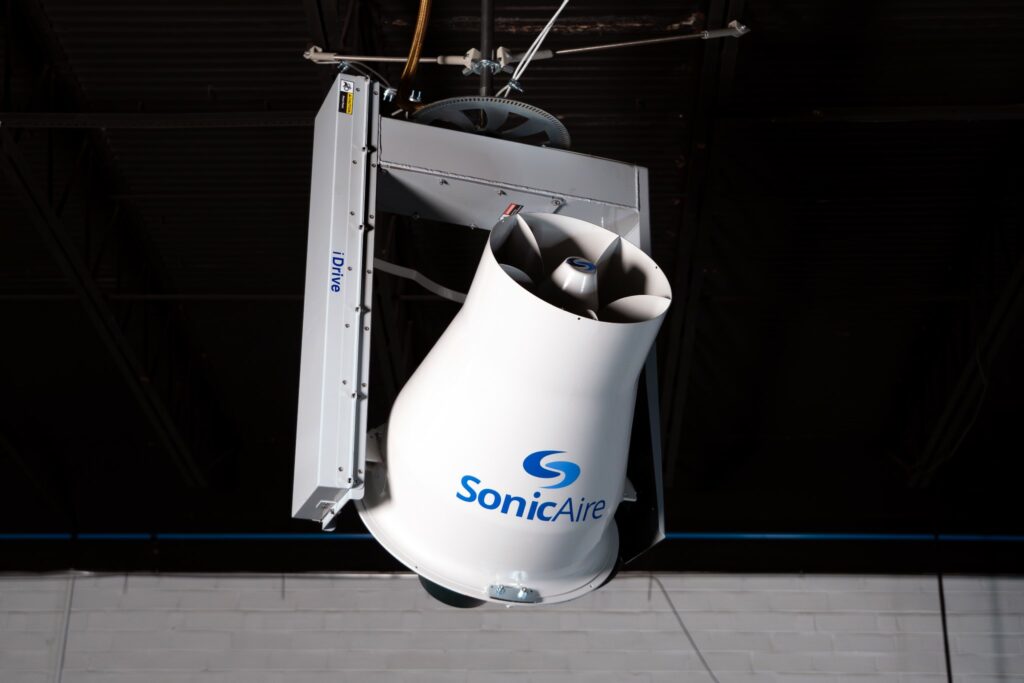

Building on its commitment to creating safer, healthier, and more efficient work environments, SonicAire introduces its latest innovation – the CIID1-certified XZ-210 and XZ-215 fans. These powerful fans come equipped with advanced features designed specifically for hazardous, highly explosible locations. Our fan systems are engineered to meet rigorous industry standards and offer unparalleled performance in preventing dust accumulation while maintaining compliance with CIID1 requirements.

The XZ-210 and XZ-215 fans utilize SonicAire’s BarrierAire™ technology to effectively disrupt airflow patterns, ensuring that combustible dust sticks to itself as it rises and then falls to the floor. Instead of settling on surfaces that you can’t easily clean. By constantly agitating the air, these fans prevent the accumulation of fine particles in overhead spaces, significantly reducing the risk of combustion and deflagration. With customizable fan layouts tailored to each facility’s unique needs, manufacturing facilities can maintain a safe and compliant environment without compromising operational efficiency.

SonicAire’s dust control fans have had meaningful success in thousands of facilities that contain combustible dust, but it’s worth noting that over half of combustible dust events occur within the food and agriculture industries. According to Canadian Forest Industries, “…food and wood products made up over 75 percent of the combustible dust fires and explosions recorded.” Luckily, SonicAire’s new fans are now certified for use in the most at-risk environments.

So what are these environments, specifically?

- Group F – Combustible carbonaceous dusts: carbon black, charcoal, coal and coke dusts

- Group G – Other combustible dusts: Chemicals, flour, grain, plastic and wood

Pro-tip: If you’re wondering if your facility is classified as a CIID1 environment, you can reference your Dust Hazard Analysis (DHA). Or check our You Ask. We Answer. video below.

In Group G environments, the fans prove their efficacy in handling a diverse range of combustible dusts. This group includes chemicals, flour, grain, plastic, and wood dust. SonicAire’s fans are equipped to address the specific challenges posed by these materials, maintaining a constant air agitation to prevent fine particles from accumulating in overhead spaces. By doing so, the fans play a crucial role in minimizing the potential for combustible dust-related incidents in facilities dealing with these substances.

The certification of the XZ-210 and XZ-215 fans for these specific environments emphasizes their versatility in diverse industrial settings, providing a targeted solution for fugitive dust control in areas that are difficult to access, and stopping production to clean them is not something you want to do.

Advantages of UL Certification for Safe and Compliant Environments

UL certification of the CIID1 fan for dust control is crucial for protecting those hazardous environments that are explosive or flammable in everyday conditions. SonicAire’s XZ-210 and XZ-215 fans hold this certification, underscoring their ability to deliver the highest levels of safety and compliance. But why is UL certification so important?

UL certification assures that a product has been thoroughly tested, evaluated, and found to meet acceptable safety standards. These requirements include robust design features and construction materials specifically engineered to mitigate the risks associated with combustible dust. Certified solutions like SonicAire’s XZ-210 and XZ-215 fans ensure that every effort has been made to provide maximum protection against potential hazards.

In addition to meeting stringent, SonicAire’s CIID1-certified fans will help your facility meet stringent OSHA standards, offering peace of mind to facility managers and business owners. By installing SonicAire dust control fans, they demonstrate their commitment to employee safety and industry best practices. Moreover, adhering to regulations helps build trust among regulatory officials, insurance adjusters, and executive committees, fostering a reputation for excellence and responsible operation. Choosing CIID1-certified solutions not only promotes safety but also instills confidence among stakeholders.

Taking Action for Safer CIID1 Environments

The dangers posed by combustible dust in Class II Division 1 (CIID1) environments demand immediate attention from manufacturing facility managers and business owners. It is vital to prioritize safety and ensure regulatory compliance to prevent catastrophic incidents and protect personnel and assets. SonicAire’s innovative dust control fans, backed by their BarrierAire™ technology, have revolutionized dust management by preventing accumulation before it escalates into a hazard.

By introducing the UL-certified XZ-210 and XZ-215 fans, SonicAire provides facility managers with hazardous environments in their facilities with an advanced solution tailored to their needs. These powerful, two-horsepower fans effectively disrupt thermal airflow patterns, causing fugitive dust particles to agglomerate, or stick together. This causes the particles to become too heavy to continue to float upward, falling to the floor to be easily swept up.

By embracing these game-changing fans, facility operators in CIID1 environments can create a safer, healthier, and more efficient work environment while remaining at the forefront of regulatory compliance.

How can you incorporate SonicAire’s innovative dust control fans into your facility to enhance safety and compliance?

Safeguard your facility from the dangers of combustible dust by beginning your journey to fully automated fugitive dust solution today. Implement a UL-certified SonicAire fan system to create a safer and more compliant work environment while maintaining uninterrupted production. Don’t wait until it’s too late – prioritize safety, protect your personnel, and ensure regulatory compliance by leveraging SonicAire’s cutting-edge dust control technology.

Request your Complimentary Dust Management Plan and ROI Analysis now and experience the transformative power of SonicAire’s BarrierAire™ technology in revolutionizing dust control in hazardous environments.

The Real Cost of Manual Dust Cleaning

It isn’t until you sit down and start adding up all of the costs the problem becomes apparent.

SonicAire Fans – A Cost-Effective Alternative

We’re not going to lie to you. Installing a SonicAire Dust Control Fan System requires an investment. There are very few facilities that can get by with a couple of fans. But the long-term benefits speak for themselves.

SonicAire fans either run for specified periods during the day or all day, depending upon your operations and dust production level. However, they use two different tactics to prevent combustible dust buildup in overhead areas.

First, they clean off higher surfaces with continual airflow. This prevents buildup and eliminates the cleaning of these areas. Second, a properly engineered system creates an Air Barrier to prevent warm air currents from bringing dust up into overhead spaces.

Let’s look at how they impact the costs we’ve highlighted above.

Measuring the Difference

Each facility is different. In manufacturing and processing, operations produce varying levels and types of fugitive dust. But each facility is likely overspending on manual cleaning or simply not cleaning enough.

When you consider the labor, equipment, and lost productivity that goes into manual cleaning practices and then add in the insurance costs, potential fines, and employee dissatisfaction. Is manually cleaning your facility really saving you money?

We’re confident our combustible dust control systems will save your facility money even with the initial investment to purchase and install. But, if you’re not 100% sold, we get it. That’s why we offer free dust management plans with ROI Analysis. These engineered plans recommend the amount and placing of fans to ensure maximum protection from dust buildup.

Click here to request your Free Dust Management Plan.

Or contact us to discuss dust control solutions for your facility.

The constant presence of combustible dust in manufacturing facilities significantly threatens safety and regulatory compliance. In Class II Division 1 (CIID1) environments, the need for effective dust control solutions becomes even more critical because of this testy environment.

Combustible dust is highly volatile and can lead to devastating incidents if not adequately managed. Manual cleaning often falls short, resulting in inefficiency, downtime, and increased risks. Thankfully, SonicAire has revolutionized dust control with their game-changing BarrierAire™ technology and their latest innovation, the CIID1 Underwriters Laboratories-certified XZ-210 and XZ-215 fans.

The Importance of Compliance and Safety in CIID1 Environments

Maintaining compliance and ensuring safety are paramount in manufacturing facilities that deal with combustible dust. These Class II Division 1 (CIID1) environments pose unique challenges due to the constant presence of highly explosible dust particles in normal conditions. Oftentimes, the amount in suspension is enough to create an environment where the air is ignitable. Neglecting proper dust control measures can have severe consequences, ranging from equipment damage and production disruptions to life-threatening incidents. Proactive steps must be taken to prevent dust accumulation and promote regulatory compliance.

The Volatility of Combustible Dust: A Persistent Threat

Combustible dust, consisting of fine particles from various materials such as wood, metal, plastics, and chemicals, poses a significant risk in industrial environments. These highly volatile particles can combust when exposed to an ignition source, leading to catastrophic incidents. Throughout history, numerous disasters have occurred due to combustible dust explosions, causing loss of life, property damage, and environmental harm. The consequences of neglecting proper dust control measures have been devastating, from grain mills to woodworking facilities.

To prevent these incidents, manufacturing facility managers and business owners must proactively mitigate dust accumulation and ensure compliance with safety regulations.

The Challenges of Manual Cleaning in CIID1 Environments

Traditionally, manual cleaning has been the go-to method for addressing dust accumulation in industrial settings. However, this approach presents several challenges, especially in CIID1 environments. One of the primary obstacles is the halt in operations during the cleaning process. Shutting down production lines for cleaning leads to downtime and negatively impacts overall productivity and profitability. Additionally, manual cleaning often turns out to be inefficient and cost-prohibitive, requiring significant labor resources and recurring expenses for cleaning vendors, services, equipment, and supplies.

To add to the headache of manual cleaning in hazardous environments, don’t forget that there are inherent risks. Workers are exposed to potential dangers while attempting to remove accumulated dust manually, increasing the likelihood of accidents and injuries. A rogue spark or a new employee who doesn’t understand that a ShopVac becomes a bomb if you use it to vacuum up dust can destroy a facility and ruin lives in a heartbeat. Because of this, finding an alternative solution ensuring safety and efficiency becomes imperative.

SonicAire Fans: A Revolutionary Solution for Dust Control

Recognizing the limitations of traditional cleaning methods, SonicAire developed a revolutionary solution for effective dust control – BarrierAire™ technology. SonicAire’s dust control fans provide a game-changing approach by preventing dust accumulation before it ever becomes a hazard. With their strategic placement within manufacturing facilities, these fans disrupt the airflow patterns that allow dust particles to settle, eliminating manual cleaning and reducing the risks associated with combustible dust.

Facility managers and business owners across various industries have witnessed immediate benefits upon implementing SonicAire’s dust control fans. Increased productivity, improved safety, reduced maintenance costs, and enhanced regulatory compliance are just a few of the advantages of installing SonicAire dust control fans.

However, Class II Division 1 environments have always had a more difficult time safely maintaining compliance – as not all environments are created equally. Due to the constant presence of volatile dust in these areas, Underwriters Laboratories, or UL Solutions, is incredibly particular in giving any product a certification declaring it safe for use. Since beginning in 1894, they have never awarded a certification for a dust control fan in CIID1 environments.

That is, until now.

The Game-Changer: Introducing the CIID1-Certified XZ-210 and XZ-215 Fans

Building on its commitment to creating safer, healthier, and more efficient work environments, SonicAire introduces its latest innovation – the CIID1-certified XZ-210 and XZ-215 fans. These powerful fans come equipped with advanced features designed specifically for hazardous, highly explosible locations. Our fan systems are engineered to meet rigorous industry standards and offer unparalleled performance in preventing dust accumulation while maintaining compliance with CIID1 requirements.

The XZ-210 and XZ-215 fans utilize SonicAire’s BarrierAire™ technology to effectively disrupt airflow patterns, ensuring that combustible dust sticks to itself as it rises and then falls to the floor. Instead of settling on surfaces that you can’t easily clean. By constantly agitating the air, these fans prevent the accumulation of fine particles in overhead spaces, significantly reducing the risk of combustion and deflagration. With customizable fan layouts tailored to each facility’s unique needs, manufacturing facilities can maintain a safe and compliant environment without compromising operational efficiency.

SonicAire’s dust control fans have had meaningful success in thousands of facilities that contain combustible dust, but it’s worth noting that over half of combustible dust events occur within the food and agriculture industries. According to Canadian Forest Industries, “…food and wood products made up over 75 percent of the combustible dust fires and explosions recorded.” Luckily, SonicAire’s new fans are now certified for use in the most at-risk environments.

So what are these environments, specifically?

- Group F – Combustible carbonaceous dusts: carbon black, charcoal, coal and coke dusts

- Group G – Other combustible dusts: Chemicals, flour, grain, plastic and wood

Pro-tip: If you’re wondering if your facility is classified as a CIID1 environment, you can reference your Dust Hazard Analysis (DHA). Or check our You Ask. We Answer. video below.

In Group G environments, the fans prove their efficacy in handling a diverse range of combustible dusts. This group includes chemicals, flour, grain, plastic, and wood dust. SonicAire’s fans are equipped to address the specific challenges posed by these materials, maintaining a constant air agitation to prevent fine particles from accumulating in overhead spaces. By doing so, the fans play a crucial role in minimizing the potential for combustible dust-related incidents in facilities dealing with these substances.

The certification of the XZ-210 and XZ-215 fans for these specific environments emphasizes their versatility in diverse industrial settings, providing a targeted solution for fugitive dust control in areas that are difficult to access, and stopping production to clean them is not something you want to do.

These environments often face substantial challenges when it comes to controlling combustible dust and stand to benefit greatly from the use of SonicAire’s XZ-210 and XZ-215 fans. A SonicAire dust control fan system provides a reliable and efficient solution for managing combustible dust and mitigating potential catastrophic explosions. By incorporating SonicAire’s CIID1-certified fans into their operations, facility operators can protect their employees and facilities, ensuring regulatory compliance while maintaining uninterrupted production.

Advantages of UL Certification for Safe and Compliant Environments

UL certification of the CIID1 fan for dust control is crucial for protecting those hazardous environments that are explosive or flammable in everyday conditions. SonicAire’s XZ-210 and XZ-215 fans hold this certification, underscoring their ability to deliver the highest levels of safety and compliance. But why is UL certification so important?

UL certification assures that a product has been thoroughly tested, evaluated, and found to meet acceptable safety standards. These requirements include robust design features and construction materials specifically engineered to mitigate the risks associated with combustible dust. Certified solutions like SonicAire’s XZ-210 and XZ-215 fans ensure that every effort has been made to provide maximum protection against potential hazards.

In addition to meeting stringent, SonicAire’s CIID1-certified fans will help your facility meet stringent OSHA standards, offering peace of mind to facility managers and business owners. By installing SonicAire dust control fans, they demonstrate their commitment to employee safety and industry best practices. Moreover, adhering to regulations helps build trust among regulatory officials, insurance adjusters, and executive committees, fostering a reputation for excellence and responsible operation. Choosing CIID1-certified solutions not only promotes safety but also instills confidence among stakeholders.

Taking Action for Safer CIID1 Environments

The dangers posed by combustible dust in Class II Division 1 (CIID1) environments demand immediate attention from manufacturing facility managers and business owners. It is vital to prioritize safety and ensure regulatory compliance to prevent catastrophic incidents and protect personnel and assets. SonicAire’s innovative dust control fans, backed by their BarrierAire™ technology, have revolutionized dust management by preventing accumulation before it escalates into a hazard.

By introducing the UL-certified XZ-210 and XZ-215 fans, SonicAire provides facility managers with hazardous environments in their facilities with an advanced solution tailored to their needs. These powerful, two-horsepower fans effectively disrupt thermal airflow patterns, causing fugitive dust particles to agglomerate, or stick together. This causes the particles to become too heavy to continue to float upward, falling to the floor to be easily swept up.

By embracing these game-changing fans, facility operators in CIID1 environments can create a safer, healthier, and more efficient work environment while remaining at the forefront of regulatory compliance.

How can you incorporate SonicAire’s innovative dust control fans into your facility to enhance safety and compliance?

Safeguard your facility from the dangers of combustible dust by beginning your journey to fully automated fugitive dust solution today. Implement a UL-certified SonicAire fan system to create a safer and more compliant work environment while maintaining uninterrupted production. Don’t wait until it’s too late – prioritize safety, protect your personnel, and ensure regulatory compliance by leveraging SonicAire’s cutting-edge dust control technology.

Request your Complimentary Dust Management Plan and ROI Analysis now and experience the transformative power of SonicAire’s BarrierAire™ technology in revolutionizing dust control in hazardous environments.

The Real Cost of Manual Dust Cleaning

It isn’t until you sit down and start adding up all of the costs the problem becomes apparent.

SonicAire Fans – A Cost-Effective Alternative

We’re not going to lie to you. Installing a SonicAire Dust Control Fan System requires an investment. There are very few facilities that can get by with a couple of fans. But the long-term benefits speak for themselves.

SonicAire fans either run for specified periods during the day or all day, depending upon your operations and dust production level. However, they use two different tactics to prevent combustible dust buildup in overhead areas.

First, they clean off higher surfaces with continual airflow. This prevents buildup and eliminates the cleaning of these areas. Second, a properly engineered system creates an Air Barrier to prevent warm air currents from bringing dust up into overhead spaces.

Let’s look at how they impact the costs we’ve highlighted above.

Measuring the Difference

Each facility is different. In manufacturing and processing, operations produce varying levels and types of fugitive dust. But each facility is likely overspending on manual cleaning or simply not cleaning enough.

When you consider the labor, equipment, and lost productivity that goes into manual cleaning practices and then add in the insurance costs, potential fines, and employee dissatisfaction. Is manually cleaning your facility really saving you money?

We’re confident our combustible dust control systems will save your facility money even with the initial investment to purchase and install. But, if you’re not 100% sold, we get it. That’s why we offer free dust management plans with ROI Analysis. These engineered plans recommend the amount and placing of fans to ensure maximum protection from dust buildup.

Click here to request your Free Dust Management Plan.

Or contact us to discuss dust control solutions for your facility.

GET YOUR FREE GUIDE:

The Real Cost of Fugitive Dust in Hard-to-Reach Spaces

What You Can’t See Can Hurt You

To help protect your workplace, we’ve compiled the following resource, The Real Cost of Fugitive Dust in Hard-to-Reach Spaces: What You Can’t See Can Hurt You. In it, we identify seven ways fugitive dust is likely impacting your facility and its profitability.

These costs go beyond housekeeping and explain why you should be preventing dust buildup to protect the bottom line, not just to stay in compliance.