Dust explosions have been a significant concern in manufacturing facilities for decades. These incidents can result in devastating consequences, including injuries, fatalities, and property damage. Facility managers and business owners must proactively prevent dust combustion events and ensure safety compliance. That’s where SonicAire dust control fans come into play. In this article, we will delve into the history of dust explosions, examine the latest incident report, explore the materials and industries involved, discuss equipment and causes, highlight OSHA citations, and ultimately introduce SonicAire as the solution to preventing dust accumulation and explosions.

The 2022 Combustible Dust Incident Report

The latest Combustible Dust Incident Report, released November 9, 2023, provides valuable insights into the scale and severity of dust explosions. These incidents led to substantial losses, including explosions, injuries, and even fatalities. This report is a stark reminder that complacency is not an option regarding safety.

Source: Dust Safety Science’s 2022 Combustible Dust Incident Report.

Quickly looking at the report, you’ll find the following statistics:

Inspections Resulting In Citations: 13

Total Initial Penalties: $1,052,255

Initial Penalty/Citation: $6,456

Total Citations: 163

Total Current Penalties: $638,269

Initial Penalty/Inspection: $45,750

Safeguarding your facility against these dust explosion risks requires continuous awareness and the implementation of safety measures. Getting a DHA is a great first step. The material and equipment will differ between facilities depending on the type of dust they produce, but there are more commonly involved pieces of the puzzle that require attention.

Materials and Industries Involved

Various materials can contribute to the risk of dust explosions. Wood, food products, metal particles, grain dust, and many others have been identified as potential fuel to cause combustion. Facility managers should know the specific materials in their operations and if their dust is combustible in order to stay compliant and safe.

Undeniably, some industries are more prone to dust explosions than others. Wood product manufacturers, food processing facilities, agriculture-related businesses, and many others face unique challenges due to the nature of their operations and their dust. Recognizing the risks associated with different industries and processes is critical to implementing effective preventive strategies.

Equipment and Causes

Several types of equipment commonly found in manufacturing facilities play a role in dust explosions. Dust collectors, storage silos, dryers, and other equipment can become potential sources of ignition if not correctly maintained. It is crucial to ensure that these systems are regularly inspected, cleaned, and serviced to prevent the build-up of combustible dust.

Some examples of equipment that impacts dust control include:

Dust Collectors

Dust collectors, designed to enhance air quality by trapping particles, paradoxically become potential ignition sources. The accumulation of fine dust within these collectors creates an environment conducive to combustion. When not properly maintained, the collected dust can ignite, setting off a chain reaction that leads to a dust explosion. Regular inspection and cleaning of dust collectors are imperative to mitigate this risk.

As a reminder, dust collectors are incredibly beneficial to your facility, but they must be regularly maintained or, like several pieces of equipment and machinery, they can become a source of genuine danger. To learn more about that, click our video below, “How to Capture the Dust Your Filtration System Misses” as part of our You Ask. We Answer. series.

Storage Silos

Storage silos, commonly used to store bulk materials, play a crucial role in various industries. However, when dust particles settle within these confined spaces, they form an explosive mixture waiting for the right spark. Ignition sources can range from static electricity to mechanical sparks during material handling. The design, maintenance, and cleaning of storage silos are pivotal in preventing the accumulation of combustible dust.

Dryers: Where Heat Meets Hazard

Drying processes, integral to numerous manufacturing operations, involve applying heat to remove moisture from materials. Unfortunately, this heat can also trigger dust explosions if not managed carefully. Dust-laden air passing through dryers can ignite if the temperature reaches a critical point. Proper ventilation, temperature control, and regular cleaning are essential safeguards to avert the risk associated with dryers.

In addition to equipment-related causes, certain activities within a facility can also contribute to dust explosion risks. Welding work, improper maintenance practices, inadequate ventilation, or even simple material accumulation can create hazardous conditions. Proper training and adherence to safety protocols are essential in mitigating these risks.

A Historical Perspective on Dust Explosions

Obviously, dust explosions are not a recent phenomenon. As far back as 1922, the NFPA warned about the dangers of combustible dust with their aptly named book, “Dust Explosions” by David James Price and Harold Hiram Brown. Over the years, numerous incidents have underscored the need for preventive measures. From the 1878 Great Mill Disaster in Minnesota to the recent Didion Milling, Inc. explosion in 2017, these events are stark reminders of the potential risks associated with dust accumulation.

Maintaining safety compliance is essential for any manufacturing facility or production business owner. Without proper prevention methods, the build-up of combustible dust can lead to catastrophic explosions. Recognizing the significance of this issue, SonicAire offers an innovative solution to mitigate the risks and also ensure regulatory compliance.

Dust Explosion History

Looking back at the past helps us understand why dust explosions are a big deal. Consider the Douglas Starch Works explosion in Cedar Rapids in 1919 or the Benxihu Colliery disaster of 1942 in China – both had severe consequences with considerable property damage and multiple fatalities. These incidents brought to light the dangers of dust explosions.

So, when facility managers examine the past, they can understand how serious it is and ensure that they take action to avoid similar incidents in their own places.

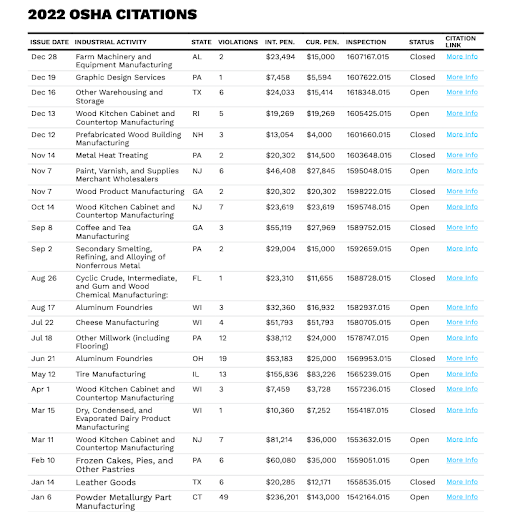

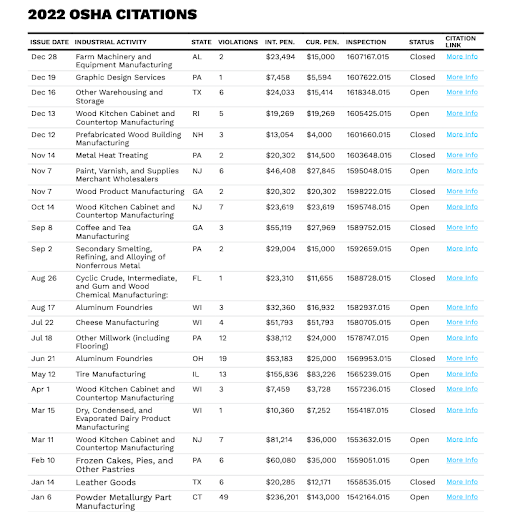

OSHA Citations

Non-compliance with safety regulations related to dust explosions can have severe consequences. The Occupational Safety and Health Administration (OSHA) takes this matter seriously and issues citations when violations occur. In 2022 alone, numerous instances occurred where facilities faced penalties due to non-compliance with safety standards.

Understanding the potential ramifications of OSHA citations incentivizes facility managers to prioritize safety and take proactive steps to prevent dust explosions. In fact, OSHA launched a National Safety Emphasis program in January 2023 to address the increasing incidents involving combustible dust in manufacturing environments.

Prevention with SonicAire Dust Control Fans

Introducing SonicAire dust control fans as a solution to preventing dust accumulation and explosions allows us to shift our focus toward proactive prevention measures. SonicAire’s BarrierAire™ technology offers a game-changing solution that prevents combustible dust issues before they escalate. By customizing fan layouts based on a facility’s unique needs, SonicAire delivers immediate benefits to businesses seeking to address fugitive dust and lint challenges.

The innovative design of SonicAire fans disrupts air patterns, keeping dust particles from settling on elevated surfaces where combustion events are more likely to occur. This cutting-edge technology effectively maintains compliance and ensures safety by continuously preventing the build-up of combustible dust.

With SonicAire dust control fans, manufacturing facility managers and production business owners can proactively protect their facilities, reduce the risk of explosions, and maintain regulatory compliance.

Ensuring Safety and Preventing Incidents

Preventing dust explosions is of utmost importance for the safety and well-being of manufacturing facilities. By examining the historical context, understanding the materials and industries involved, recognizing equipment-related causes, being aware of OSHA citations, and implementing preventive measures such as SonicAire dust control fans, facility managers can effectively mitigate the risks associated with combustible dust.

The role of SonicAire in this process cannot be overstated. Our innovative technology provides a proactive solution that prevents dust accumulation and reduces the likelihood of explosions. Our expertise and customized fan layouts allow businesses to maintain regulatory compliance, safeguard their facilities, and protect employees from potential harm. All without having to find and then pay someone to do it and shutting down operations while doing so.

To ensure the safety of your own facility, request a quote from SonicAire and join countless other manufacturing facilities that have embraced this revolutionary approach to prevent dust explosions. Don’t wait until it’s too late – prioritize safety, health, and efficiency and make your facility a better place for everyone.

The Real Cost of Manual Dust Cleaning

It isn’t until you sit down and start adding up all of the costs the problem becomes apparent.

SonicAire Fans – A Cost-Effective Alternative

We’re not going to lie to you. Installing a SonicAire Dust Control Fan System requires an investment. There are very few facilities that can get by with a couple of fans. But the long-term benefits speak for themselves.

SonicAire fans either run for specified periods during the day or all day, depending upon your operations and dust production level. However, they use two different tactics to prevent combustible dust buildup in overhead areas.

First, they clean off higher surfaces with continual airflow. This prevents buildup and eliminates the cleaning of these areas. Second, a properly engineered system creates an Air Barrier to prevent warm air currents from bringing dust up into overhead spaces.

Let’s look at how they impact the costs we’ve highlighted above.

Measuring the Difference

Each facility is different. In manufacturing and processing, operations produce varying levels and types of fugitive dust. But each facility is likely overspending on manual cleaning or simply not cleaning enough.

When you consider the labor, equipment, and lost productivity that goes into manual cleaning practices and then add in the insurance costs, potential fines, and employee dissatisfaction. Is manually cleaning your facility really saving you money?

We’re confident our combustible dust control systems will save your facility money even with the initial investment to purchase and install. But, if you’re not 100% sold, we get it. That’s why we offer free dust management plans with ROI Analysis. These engineered plans recommend the amount and placing of fans to ensure maximum protection from dust buildup.

Click here to request your Free Dust Management Plan.

Or contact us to discuss dust control solutions for your facility.

Dust explosions have been a significant concern in manufacturing facilities for decades. These incidents can result in devastating consequences, including injuries, fatalities, and property damage. Facility managers and business owners must proactively prevent dust combustion events and ensure safety compliance. That’s where SonicAire dust control fans come into play. In this article, we will delve into the history of dust explosions, examine the latest incident report, explore the materials and industries involved, discuss equipment and causes, highlight OSHA citations, and ultimately introduce SonicAire as the solution to preventing dust accumulation and explosions.

The 2022 Combustible Dust Incident Report

The latest Combustible Dust Incident Report, released November 9, 2023, provides valuable insights into the scale and severity of dust explosions. These incidents led to substantial losses, including explosions, injuries, and even fatalities. This report is a stark reminder that complacency is not an option regarding safety.

Source: Dust Safety Science’s 2022 Combustible Dust Incident Report.

Quickly looking at the report, you’ll find the following statistics:

Inspections Resulting In Citations: 13

Total Initial Penalties: $1,052,255

Initial Penalty/Citation: $6,456

Total Citations: 163

Total Current Penalties: $638,269

Initial Penalty/Inspection: $45,750

Safeguarding your facility against these dust explosion risks requires continuous awareness and the implementation of safety measures. Getting a DHA is a great first step. The material and equipment will differ between facilities depending on the type of dust they produce, but there are more commonly involved pieces of the puzzle that require attention.

Materials and Industries Involved

Various materials can contribute to the risk of dust explosions. Wood, food products, metal particles, grain dust, and many others have been identified as potential fuel to cause combustion. Facility managers should know the specific materials in their operations and if their dust is combustible in order to stay compliant and safe.

Undeniably, some industries are more prone to dust explosions than others. Wood product manufacturers, food processing facilities, agriculture-related businesses, and many others face unique challenges due to the nature of their operations and their dust. Recognizing the risks associated with different industries and processes is critical to implementing effective preventive strategies.

Equipment and Causes

Several types of equipment commonly found in manufacturing facilities play a role in dust explosions. Dust collectors, storage silos, dryers, and other equipment can become potential sources of ignition if not correctly maintained. It is crucial to ensure that these systems are regularly inspected, cleaned, and serviced to prevent the build-up of combustible dust.

Some examples of equipment that impacts dust control include:

Dust Collectors

Dust collectors, designed to enhance air quality by trapping particles, paradoxically become potential ignition sources. The accumulation of fine dust within these collectors creates an environment conducive to combustion. When not properly maintained, the collected dust can ignite, setting off a chain reaction that leads to a dust explosion. Regular inspection and cleaning of dust collectors are imperative to mitigate this risk.

As a reminder, dust collectors are incredibly beneficial to your facility, but they must be regularly maintained or, like several pieces of equipment and machinery, they can become a source of genuine danger. To learn more about that, click our video below, “How to Capture the Dust Your Filtration System Misses” as part of our You Ask. We Answer. series.

Storage Silos

Storage silos, commonly used to store bulk materials, play a crucial role in various industries. However, when dust particles settle within these confined spaces, they form an explosive mixture waiting for the right spark. Ignition sources can range from static electricity to mechanical sparks during material handling. The design, maintenance, and cleaning of storage silos are pivotal in preventing the accumulation of combustible dust.

Dryers: Where Heat Meets Hazard

Drying processes, integral to numerous manufacturing operations, involve applying heat to remove moisture from materials. Unfortunately, this heat can also trigger dust explosions if not managed carefully. Dust-laden air passing through dryers can ignite if the temperature reaches a critical point. Proper ventilation, temperature control, and regular cleaning are essential safeguards to avert the risk associated with dryers.

In addition to equipment-related causes, certain activities within a facility can also contribute to dust explosion risks. Welding work, improper maintenance practices, inadequate ventilation, or even simple material accumulation can create hazardous conditions. Proper training and adherence to safety protocols are essential in mitigating these risks.

A Historical Perspective on Dust Explosions

Obviously, dust explosions are not a recent phenomenon. As far back as 1922, the NFPA warned about the dangers of combustible dust with their aptly named book, “Dust Explosions” by David James Price and Harold Hiram Brown. Over the years, numerous incidents have underscored the need for preventive measures. From the 1878 Great Mill Disaster in Minnesota to the recent Didion Milling, Inc. explosion in 2017, these events are stark reminders of the potential risks associated with dust accumulation.

Maintaining safety compliance is essential for any manufacturing facility or production business owner. Without proper prevention methods, the build-up of combustible dust can lead to catastrophic explosions. Recognizing the significance of this issue, SonicAire offers an innovative solution to mitigate the risks and also ensure regulatory compliance.

Dust Explosion History

Looking back at the past helps us understand why dust explosions are a big deal. Consider the Douglas Starch Works explosion in Cedar Rapids in 1919 or the Benxihu Colliery disaster of 1942 in China – both had severe consequences with considerable property damage and multiple fatalities. These incidents brought to light the dangers of dust explosions.

So, when facility managers examine the past, they can understand how serious it is and ensure that they take action to avoid similar incidents in their own places.

OSHA Citations

Non-compliance with safety regulations related to dust explosions can have severe consequences. The Occupational Safety and Health Administration (OSHA) takes this matter seriously and issues citations when violations occur. In 2022 alone, numerous instances occurred where facilities faced penalties due to non-compliance with safety standards.

Understanding the potential ramifications of OSHA citations incentivizes facility managers to prioritize safety and take proactive steps to prevent dust explosions. In fact, OSHA launched a National Safety Emphasis program in January 2023 to address the increasing incidents involving combustible dust in manufacturing environments.

Prevention with SonicAire Dust Control Fans

Introducing SonicAire dust control fans as a solution to preventing dust accumulation and explosions allows us to shift our focus toward proactive prevention measures. SonicAire’s BarrierAire™ technology offers a game-changing solution that prevents combustible dust issues before they escalate. By customizing fan layouts based on a facility’s unique needs, SonicAire delivers immediate benefits to businesses seeking to address fugitive dust and lint challenges.

The innovative design of SonicAire fans disrupts air patterns, keeping dust particles from settling on elevated surfaces where combustion events are more likely to occur. This cutting-edge technology effectively maintains compliance and ensures safety by continuously preventing the build-up of combustible dust.

With SonicAire dust control fans, manufacturing facility managers and production business owners can proactively protect their facilities, reduce the risk of explosions, and maintain regulatory compliance.

Ensuring Safety and Preventing Incidents

Preventing dust explosions is of utmost importance for the safety and well-being of manufacturing facilities. By examining the historical context, understanding the materials and industries involved, recognizing equipment-related causes, being aware of OSHA citations, and implementing preventive measures such as SonicAire dust control fans, facility managers can effectively mitigate the risks associated with combustible dust.

The role of SonicAire in this process cannot be overstated. Our innovative technology provides a proactive solution that prevents dust accumulation and reduces the likelihood of explosions. Our expertise and customized fan layouts allow businesses to maintain regulatory compliance, safeguard their facilities, and protect employees from potential harm. All without having to find and then pay someone to do it and shutting down operations while doing so.

To ensure the safety of your own facility, request a quote from SonicAire and join countless other manufacturing facilities that have embraced this revolutionary approach to prevent dust explosions. Don’t wait until it’s too late – prioritize safety, health, and efficiency and make your facility a better place for everyone.

The Real Cost of Manual Dust Cleaning

It isn’t until you sit down and start adding up all of the costs the problem becomes apparent.

SonicAire Fans – A Cost-Effective Alternative

We’re not going to lie to you. Installing a SonicAire Dust Control Fan System requires an investment. There are very few facilities that can get by with a couple of fans. But the long-term benefits speak for themselves.

SonicAire fans either run for specified periods during the day or all day, depending upon your operations and dust production level. However, they use two different tactics to prevent combustible dust buildup in overhead areas.

First, they clean off higher surfaces with continual airflow. This prevents buildup and eliminates the cleaning of these areas. Second, a properly engineered system creates an Air Barrier to prevent warm air currents from bringing dust up into overhead spaces.

Let’s look at how they impact the costs we’ve highlighted above.

Measuring the Difference

Each facility is different. In manufacturing and processing, operations produce varying levels and types of fugitive dust. But each facility is likely overspending on manual cleaning or simply not cleaning enough.

When you consider the labor, equipment, and lost productivity that goes into manual cleaning practices and then add in the insurance costs, potential fines, and employee dissatisfaction. Is manually cleaning your facility really saving you money?

We’re confident our combustible dust control systems will save your facility money even with the initial investment to purchase and install. But, if you’re not 100% sold, we get it. That’s why we offer free dust management plans with ROI Analysis. These engineered plans recommend the amount and placing of fans to ensure maximum protection from dust buildup.

Click here to request your Free Dust Management Plan.

Or contact us to discuss dust control solutions for your facility.

GET YOUR FREE GUIDE:

The Real Cost of Fugitive Dust in Hard-to-Reach Spaces

What You Can’t See Can Hurt You

To help protect your workplace, we’ve compiled the following resource, The Real Cost of Fugitive Dust in Hard-to-Reach Spaces: What You Can’t See Can Hurt You. In it, we identify seven ways fugitive dust is likely impacting your facility and its profitability.

These costs go beyond housekeeping and explain why you should be preventing dust buildup to protect the bottom line, not just to stay in compliance.