The Way It Was Worked, But We Knew It Could Be Better.

When we started offering dust management solutions to facilities, the overall goal was to provide a well-engineered solution to a significant problem. We created our dust control fans as that solution, and the result was a success; our fans are proven to prevent combustible dust buildup and do so successfully for thousands of facilities around the globe.

We use our Proven Process with each and every customer. It utilizes specialized engineers to develop a plan for each organization investing in a dust control solution. This solution will depend on the type of dust generated, the pace of accumulation, and the facility layout. That means you can be confident that once SonicAire fans are appropriately installed, you’ll have fewer fugitive dust problems than ever before.

Previously, our fans and this Proven Process (and excellent customer service, including our compliance guarantee, check-ins, and follow-ups) wrapped up what SonicAire offered. After purchasing and receiving our fans, our customers had the burden of finding a contractor in their local area whom they trusted to install them.

After the client’s contractor installed their fans, we arranged an inspection from a SonicAire representative. Our specialists went to the facility, inspected the installation and the equipment, then walked through any questions or uncertainties our client had with the new equipment. The process took a little longer, but when SonicAire’s representative left, everyone was confident in the fans and how the fans would protect the facility from fugitive dust.

And it was good; the system worked well for all parties.

But it wasn’t good enough for us.

SonicAire Won’t Leave You Stranded

Our customers wanted a turnkey solution, so SonicAire worked to create a team of authorized installers specially trained and certified to install our combustible dust control fans. Our clients will no longer need a third-party contractor to install our fans – we have it covered!

While we do everything we can to ensure our customers are satisfied with their dust control fans, it can be challenging when we’re not handling the installation. We’ve seen fans installed with blades turning in the wrong direction, mounted unsafely, and even blocked fire suppression systems. We don’t ever want you to be unsatisfied or unprotected with your purchase, and creating SonicAire Installation Services was the way to solve this issue for our customers.

SonicAire authorized installers are trained experts at safely and efficiently installing our fans. They have been qualified on the latest installation techniques and safety protocols to ensure that our clients’ fans are installed correctly, to our engineered layout made specifically for your facility, and to the highest standard.

By offering authorized installation, we are taking the stress and uncertainty out of the installation process for our clients. They can trust that their investment in a combustible dust control fan system will be installed correctly and comply with local codes and regulations.

Walkthrough of Your New Fans

When one of our authorized installation teams installs your SonicAire fans, you’ll also receive extra guidance on their operation. You should expect several discussions with our sales and engineering team about how to operate your fans and how they’ll perform along the way, but after installation, you’ll see the plan in action.

Your new control panel, for example, will not be a mystery in your facility. You’ll have experts on-site to answer your questions and not just explain but demonstrate how you’ll control and operate your fans. They’ll go over some troubleshooting options and tell you more about dust control fan operation than you ever thought you’d need to know.

Feeling confident that your investment is a good use of company resources is pretty important.

Startup Inspection

Once your SonicAire dust control fans are installed, a representative will visit your facility to inspect your fans in person to check for any manufacturing defects or improper installation techniques. This inspection can occur directly following your fan installation. If that’s the case, you’ll have everything done at once, and your facility will immediately maintain an environment that’s safe and compliant with fugitive, combustible dust.

The safety of our clients’ employees and facilities is our top priority. By offering authorized installation, we ensure that their combustible dust control fans are installed correctly and safely by providing certified installation. We’ll leave you with a way to contact us if you have any questions or concerns regarding your fan, and we welcome the call!

If you want to avoid calls, though, you may be able to fix the problem by watching our video, The Top 3 SonicAire Parts and Services Requests, below.

SonicAire’s Pledge to You

The SonicAire-engineered solution we’ve custom-designed breaks endless manual cleaning cycles and gives a new level of confidence in dust compliance and safety. With a dust-free ceiling and cleaner, clearer air, employees can focus on value-added work that adds to the bottom line. We want you to be as confident as we are in installing SonicAire equipment, so take the time to review this proposal, and don’t hesitate to ask us any questions you may have. You’ll be able to rest more easily knowing that you have a cleaner, safer, and more efficient work environment than you’ve ever had before!

Contact us today to learn more about how our authorized installers can help keep your facility safe.

The Real Cost of Manual Dust Cleaning

It isn’t until you sit down and start adding up all of the costs the problem becomes apparent.

SonicAire Fans – A Cost-Effective Alternative

We’re not going to lie to you. Installing a SonicAire Dust Control Fan System requires an investment. There are very few facilities that can get by with a couple of fans. But the long-term benefits speak for themselves.

SonicAire fans either run for specified periods during the day or all day, depending upon your operations and dust production level. However, they use two different tactics to prevent combustible dust buildup in overhead areas.

First, they clean off higher surfaces with continual airflow. This prevents buildup and eliminates the cleaning of these areas. Second, a properly engineered system creates an Air Barrier to prevent warm air currents from bringing dust up into overhead spaces.

Let’s look at how they impact the costs we’ve highlighted above.

Measuring the Difference

Each facility is different. In manufacturing and processing, operations produce varying levels and types of fugitive dust. But each facility is likely overspending on manual cleaning or simply not cleaning enough.

When you consider the labor, equipment, and lost productivity that goes into manual cleaning practices and then add in the insurance costs, potential fines, and employee dissatisfaction. Is manually cleaning your facility really saving you money?

We’re confident our combustible dust control systems will save your facility money even with the initial investment to purchase and install. But, if you’re not 100% sold, we get it. That’s why we offer free dust management plans with ROI Analysis. These engineered plans recommend the amount and placing of fans to ensure maximum protection from dust buildup.

Click here to request your Free Dust Management Plan.

Or contact us to discuss dust control solutions for your facility.

If you work in a facility that deals with combustible dust on a daily basis, you probably know the regulations and standards you’re required to comply with in order to maintain a safe facility. (Or, at the very least, to save yourself from OSHA fines.) The National Fire Prevention Association (NFPA) creates standards for nearly everything that presents a risk for fire or explosion.

And that includes combustible dust.

But when you compare the standards the NFPA has created for general combustible dust use against the standards they’ve created for industry-specific combustible dust, it can cause some confusion. If the fundamentals of combustible dust give one kind of guidance, but the directives on a specific type of dust (grain dust, for example) provide conflicting instruction, what should you do?

It’s worth noting that there are already several standards on combustible dust currently. They cover everything from the fundamentals to general guidance to an individual standard for each industry dealing with combustible dust. It adds up to a lot of standards that any person working with combustible dust must understand and comply with. It may not be impossible, but it certainly isn’t easy; a fact the NFPA understands and is attempting to improve.

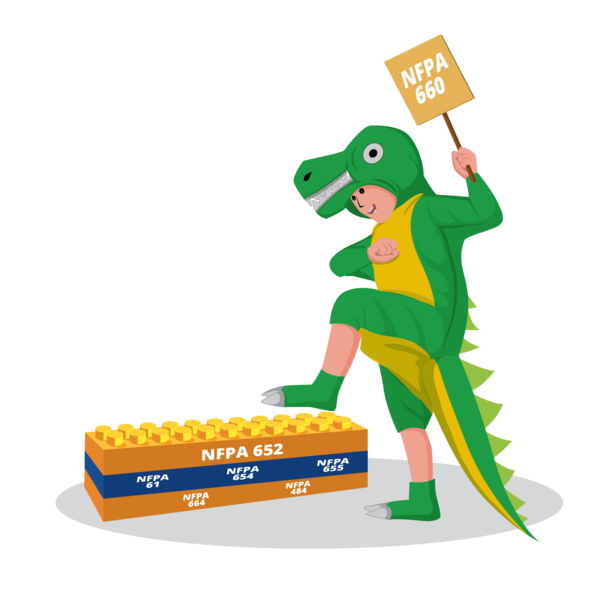

The new NFPA standard 660 seeks to make these complications a thing of the past.

What is NFPA 660?

First and foremost, NFPA 660 consolidates standards on combustible dust. It will make it a “one-stop-shop” for combustible dust. It uses the information in NFPA standards 652, 61, 484, 654, 655, and 664 to create this new standard. So while most of the information will be “recycled” from the existing standards, some of it will be a closer look at the specifics for each commodity and industry.

So How Will the Standard Break Down?

- Chapters 1-9: Deals with fundamentals and replaces NFPA 652, Standard on the Fundamentals of Combustible Dust

- Chapter 10: Replaces NFPA 61, Standard for the Prevention of Fires and Dust Explosions in Agricultural and Food Processing Facilities, regarding Agriculture and Food

- Chapter 11: Replaces NFPA 484, Standard for Combustible Metals

- Chapter 12: Replaces NFPA 654, Standard for the Prevention of Fire and Dust Explosions from the Manufacturing, Processing, and Handling of Combustible Particulate Solids

- Chapter 13: Replaces NFPA 655, Standard for Prevention of Sulfur Fires and Explosions

- Chapter 14: Replaces NFPA 664, Standard for the Prevention of Fires and Explosions in Wood Processing and Woodworking Facilities

What happens to NFPA standards 652, 61, 484, 654, 655, and 664?

Mostly, the standards currently dealing with combustible dust will become obsolete after NFPA 660 is approved and published. The good news is that the new standard will simply reiterate a significant amount of the content within each standard, but the bad news is that, yes, your old “how-to” will no longer be your “go-to.”

Not all standards dealing with all combustion will be obsolete, though, nor will they be consolidated in 660. There was some debate on the inclusion of the general “how-to” standards, but it looks like the conclusion was to reference the standards but not consolidate them. That means that, for example, NFPA 68: Standard on Explosion Protection by Deflagration Venting and NFPA 69: Standard on Explosion Prevention Systems will not be included in the consolidation but will be referred to when applicable in NFPA 660.

What’s Likely to Change in NFPA 660?

When it comes to the fundamentals, not a lot has changed. In fact, if you’re already doing what you should be doing for combustible dust management, a lot will remain the same. You’ll still need to have a Dust Hazard Analysis (DHA) performed and maintained for your facility, and you’ll still need to control your combustible dust. The regulations about venting and dust storage and documentation requirements will all remain the same.

However, you should note that the industry-specific standards do have some changes, most notably the standards on metals. Due to the extreme range of hazards in the current standard NFPA 484 Standard for Combustible Metals (and future chapter 11 of NFPA 660), you should expect more of a deep dive into the safety and combustion prevention of this standard. It may keep your everyday procedures the same, or it may flip a few of your policies on their head.

In Jason Krbec’s presentation at the 2021 Global Dust Safety Conference, he addresses the most likely update we’ll see. “There will be expanded detail on housekeeping. You’re going to see a lot of improvement in that section.” Krbec says. “Housekeeping is usually the first line of defense against some of these combustible dust incidents, so it’s very important. This will definitely be in the code.”

Other updates you can expect circle back to the consolidation of all combustible dust standards. Because each standard had its own committee of experts to write and publish it, the fundamentals of combustible dust (NFPA 652) were open to interpretation.

According to a podcast with Laura Moreno, Standards Lead, Industrial and Chemical Engineering at NFPA, on Dust Safety Science, the different interpretations were causing inconsistent requirements. “The NFPA standards cover all industries and occupations associated with combustible dust, but they had some inconsistent requirements. There were also comments about how [this fact] could limit the effectiveness of their use, as well as how OSHA shouldn’t adopt NFPA standards because it’s hard to determine which requirements apply where.”

What Happens in the Event of a Conflict?

What Happens in the Event of a Conflict?

The NFPA understands that each industry has its own specific needs regarding combustible dust. If the fundamental chapters present information that doesn’t align with the data or instruction in the industry-specific chapter, the industry-specific will effectively trump the fundamental instructions.

By establishing this from the onset, the NFPA hopes to de-conflict several of the unforeseen issues of the past.

How Will I Be Able to Get It?

The NFPA is a not-for-profit organization that the federal government doesn’t control. As such, once published, the standard, like all others, will be available for purchase. Funds generated by purchases are used to create standards that keep your facility safe and compliant.

Code or Standard?

Currently, the NFPA 660 will be a standard just like those it will consolidate. However, because the intent is to become a “super standard” that becomes the final word on combustible dust, the NFPA hopes this standard will also become a code. Their goal is to develop 660 similarly to the National Electrical Code (formerly NFPA standard 70).

While a standard is not a law, a code could be, and the hope is that if accepted nationally, 660 will be the universal and unquestioned standard for combustible dust. OSHA would likely inspect facilities using the regulations of 660, and the suggestions for safety would become mandated. The consistency of a legal requirement would keep facilities safer and leave less room for unsafe shortcuts.

What Can YOU Do?

With an estimated publication date of Fall 2024, the standard is currently up for public input and will be until January 5, 2023.

The standard is currently under the public comment portion of its publication, which means it’s open to anyone to make suggestions and comments. The NFPA will immediately disregard any comment that requests endorsing any product, so you can’t use this as an opportunity to push your product.

We believe that if the NFPA could recommend a product without showing favoritism or causing problems for other businesses, they’d mention us as the best bet for combustible dust management. Once it’s finalized, we expect most of the regulations for controlling and preventing dust build-up to be virtually irrelevant to a facility with SonicAire fans installed.

SonicAire will remain your best choice for maintaining a safe and compliant facility.

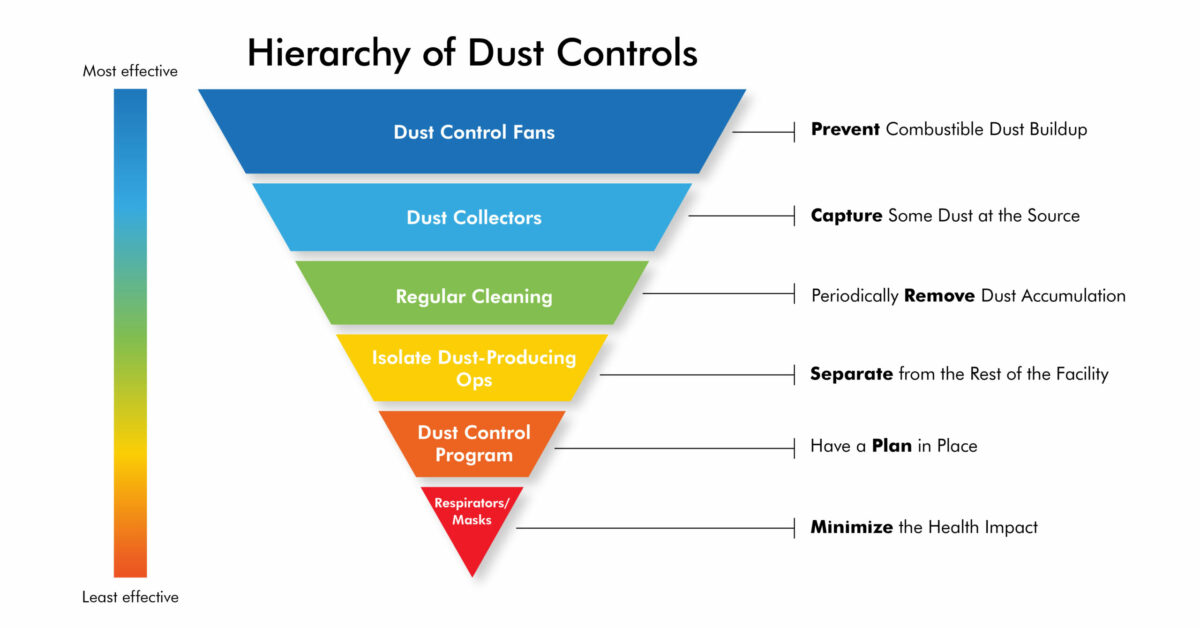

Remember that the best form of protection against combustible dust is the prevention of it. Luckily, SonicAire offers that option to you with our dust control fans. When evaluating your options for explosive dust mitigation, always reference the hierarchy of combustible dust control for your safest option to remain compliant. (See below)

Public Workshop

This virtual workshop ran from Dec 5-9, 2022 but will be available for replay until January 5, 2023.

By registering, you’ll receive templates and examples for your response, as well as guides for navigating the NFPA website. You’ll even have the chance to submit a survey that the Dust Safety Academy will use to build lesson plans for the workshop.

Will This Affect Your SonicAire Fans?

Absolutely not. The standard will deal with the details of managing combustible dust and preventing dangers that its build-up can cause. With SonicAire fans, you won’t have to change how you handle your combustible dust. You’ll still be preventing it from ever becoming a problem, so those who already have SonicAire dust control fans installed in their facilities will be ahead of the curve for dust control.

The Real Cost of Manual Dust Cleaning

It isn’t until you sit down and start adding up all of the costs the problem becomes apparent.

SonicAire Fans – A Cost-Effective Alternative

We’re not going to lie to you. Installing a SonicAire Dust Control Fan System requires an investment. There are very few facilities that can get by with a couple of fans. But the long-term benefits speak for themselves.

SonicAire fans either run for specified periods during the day or all day, depending upon your operations and dust production level. However, they use two different tactics to prevent combustible dust buildup in overhead areas.

First, they clean off higher surfaces with continual airflow. This prevents buildup and eliminates the cleaning of these areas. Second, a properly engineered system creates an Air Barrier to prevent warm air currents from bringing dust up into overhead spaces.

Let’s look at how they impact the costs we’ve highlighted above.

Measuring the Difference

Each facility is different. In manufacturing and processing, operations produce varying levels and types of fugitive dust. But each facility is likely overspending on manual cleaning or simply not cleaning enough.

When you consider the labor, equipment, and lost productivity that goes into manual cleaning practices and then add in the insurance costs, potential fines, and employee dissatisfaction. Is manually cleaning your facility really saving you money?

We’re confident our combustible dust control systems will save your facility money even with the initial investment to purchase and install. But, if you’re not 100% sold, we get it. That’s why we offer free dust management plans with ROI Analysis. These engineered plans recommend the amount and placing of fans to ensure maximum protection from dust buildup.

Click here to request your Free Dust Management Plan.

Or contact us to discuss dust control solutions for your facility.

GET YOUR FREE GUIDE:

The Real Cost of Fugitive Dust in Hard-to-Reach Spaces

What You Can’t See Can Hurt You

To help protect your workplace, we’ve compiled the following resource, The Real Cost of Fugitive Dust in Hard-to-Reach Spaces: What You Can’t See Can Hurt You. In it, we identify seven ways fugitive dust is likely impacting your facility and its profitability.

These costs go beyond housekeeping and explain why you should be preventing dust buildup to protect the bottom line, not just to stay in compliance.

What Happens in the Event of a Conflict?

What Happens in the Event of a Conflict?